- Next Generation Cooling Solutions for High-Capacity Battery Chargers of Electric Vehicles

- Urban building energy model for the City of Surrey

- Development of Waste-Heat Driven Sorption Air Conditioner

- From Waste to Clean Food

- Passive Cooling Systems

- Graphite Thermal Products

- Green AC-R in Service Vehicles

- Electronics Cooling

- Adsorption Cooling

- PEM Fuel Cells

- HVAC

- Insulation

- Battery Thermal Management

- Microstructured Materials

The LAEC seeks to understand and solve fundamental problems at multiscale levels to improve energy conversion efficiency in devices such as compact heat exchangers, fuel cells, batteries, and refrigeration systems. The following highlights some of the current research projects in our group.

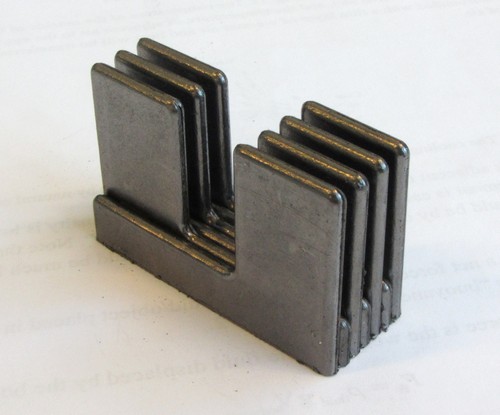

Next Generation Cooling Solutions for High-Capacity Battery Chargers of Electric Vehicles

This project is a collaboration between Delta-Q Technologies (Burnaby, BC), Terrella Energy Systems (Mission, BC), and Prof. Majid Bahrami (Mechatronic Systems Engineering, SFU) to commercialize novel and efficient cooling solutions for light electric vehicles (LEVs) battery chargers. LEVs are one of the largest and fastest growing electric vehicle markets. A LEV is a land vehicle propelled by an electric motor that uses a battery and has two to four wheels. Efficient cooling of components, which is key for reliable function of power electronics, is particularly challenging due to the packed arrangement of components, and limited available surface area for heat transfer. Enhanced cooling by compact, light, and cost-effective heat removal systems (heat sinks, heat spreaders, and fans) is essential to the competitiveness of high-performance power electronics systems in the market. It is also desirable to replace the parasitic power consumption of fans with passively-cooled systems. A key innovation in this research is the use of graphite. Graphite has superior thermo-mechanical properties, including heat removal capacity, lightweight, and corrosion resistance, that makes it excellent for thermal management of power electronics and auto industry. The roll embossing process developed at Terrella Energy Systems for high-volume, cost-effective manufacturing of micro-patterned, flexible graphite sheets enables the manufacture of sophisticated graphite heat sinks. In addition to enhanced thermal performance, the proposed graphite heat sinks can reduce the Electromagnetic Interference (EMI) within electronic devices, which would a major advantage for Delta-Q. Canada is the fourth largest exporter of raw graphite. The proposed graphite products aim at the strategic $17 billion/year industrial heat exchangers and a $12 billion/year thermal management products markets and has a great potential to revolutionize this industry.

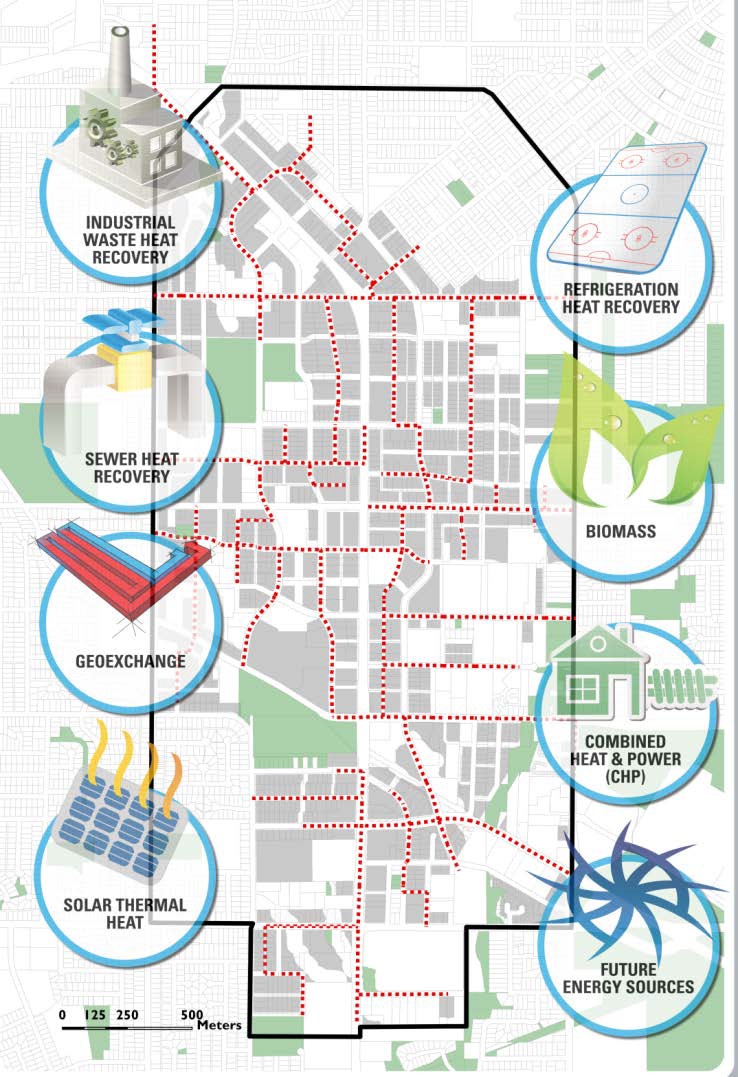

Urban building energy model for the City of Surrey

The United Nations estimates that the number of city dwellers worldwide will grow until 2030 at a net rate of about two million per week. Cities are hubs of social, cultural, and economic activity as well as centers of high energy consumption and related greenhouse gas emissions. By mid-century, energy demand in cities will probably double because of population growth and urbanization. In order to satisfy energy security and limit climate change, entire urban areas are being transformed with a strong emphasis on energy efficiency. The City of Surrey, a major city in British Columbia (BC), has built a central district energy (DE) system to provide cost-efficient and environmentally sustainable heat and hot water to buildings in its downtown core. The proposed research project will establish a collaborative relationship between Dr. Bahrami at Simon Fraser University (SFU) and the City of Surrey. It aims to develop an urban building energy model (UBEM) for the City of Surrey's DE system. A systematic approach will be undertaken to establish DE system demands and assess integration of a number of renewable sources, such as solar, geothermal, and biofuel energy into the DE central system. The proposed research is anticipated to result in significant economic gains for BC. DE system modeling is expected to become a key planning tool for utilities, urban planners, and even architects working on neighborhood-level projects in Surrey and other municipalities since it is applicable to all Canadian municipalities. The innovations in this area will help reduce Canada's carbon footprint and transform the urban building sector.

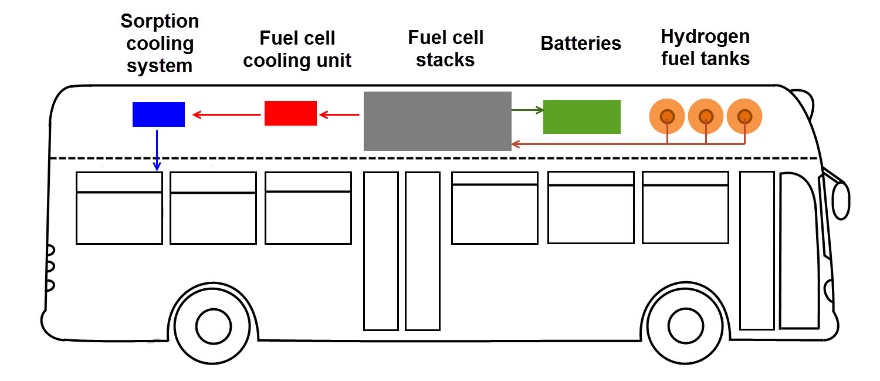

Development of Waste-Heat Driven Sorption Air Conditioner

Conventional air conditioners (ACs) consume significant amounts of electricity, generated mainly from burning fossil fuels. AC and refrigeration units use almost 15% of the electricity produced globally. A surge in global use of AC systems poise to place unparalleled demand on the energy supply and significantly curtail global climate change plans. The proposed project aims to accelerate the development of an efficient and compact sorption air conditioning (SAC) pre-market prototype which is driven by waste-heat (temperatures below 80 °C) that is free and readily available from internal combustion engines, fuel cells, natural gas, or other renewable sources such as solar thermal panels. The proposed SAC system is comprised of a sorption bed and a combined evaporator-condenser unit, assembled inside a sealed chamber. The focus of this development will be on clean transportation and net-zero buildings, where reducing carbon footprint and sustainability is a key mandate. The project relies on the integration of an advanced sorption unit and a patent-pending micro capillary-assisted low-pressure evaporator technology, US provisional Patent Application, No. 62/623406. The project benefits from the participation of market leaders in clean transportation: New Flyer Industries (a Manitoba bus manufacturer) and Ballard Power Systems (a British Columbia technology leader in fuel cell buses). The proposed project includes development of novel consolidated sorption materials, ultra-compact heat exchangers, and 3D printed prototype with strong potentials for further intellectual property generation and market introduction of new sustainable energy conversion systems that are beneficial to all Canadians and beyond.

From Waste to Clean Food

Providing potable water and clean food are now priorities and daunting challenges for every country due to the combination of dramatic global weather pattern change, disastrous man-made pollution, and a rapidly growing world population. One promising solution is growing food and medicine in an engineered environment in closed greenhouses for optimum and reliable plant growth year-round. With an estimated 60% of the energy produced globally converted to low-grade waste-heat, this research program aims to develop and test the next generation of closed greenhouse, equipped with waste-heat driven technologies, to sustainably produce clean food and fresh water under any climatic conditions. LAEC is partnering with the Institute for Sustainable Horticulture at Kwantlen Polytechnic University, Argus Control Systems, the BC Greenhouse Growers' Association and Nexus Biofuel in this initiative.

Passive Cooling Systems for High Power Battery Chargers

Delta-Q Technologies is major manufacturer of battery chargers for electric vehicles, golf carts, forklifts, and aerial work platforms. A number of failrue mechanisms in electronic devices stem from overheating, and the trend in industry is to reduce size and increase power, which doubly impacts the cooling needs. Therefore, cooling has become a limiting factor in the development of higher power-density battery chargers, and 10-15% of the the input power in a battery charger is already being consumed for cooling of the electronic components. This project aims to develop next-generation passive cooling solutions, featuring emerging graphite thermal interface materials, heat pipes, and new, efficient naturally-cooled heat sinks.

Improved Graphite Thermal Management Products

Graphite has high thermal conductivity, low density, negligible coefficient of thermal expansion, and high corrosion resistance. These properties make graphite an excellent material for applications in energy conversion systems, electronics cooling, and heat exchangers. Terrella Energy Systems Ltd. has developed new graphite-based thermal management products manufactured by advanced roll embossing and laminating processes. LAEC, in collaboration with Sheridan College, is working with Terrella to improve the performance and market competitiveness of graphite-sheet-based heat sinks, thermal interface materials, and heat exchangers.

Air Conditioning and Refrigeration Systems for Service Vehicles

This research program is working to eliminate the need for idling and to improve the overall efficiency of air-conditioning and refrigeration (A/C-R) systems in service vehicles, including long-haul trucks, reefers and buses. The project is a collaborative research program between Simon Fraser University and the University of Waterloo, and enjoys the full support and close collaboration of three industrial partners: Cool-It; CrossChasm Technologies and Saputo Dairy Products Canada. The long-term goal is to improve the fuel economy of service vehicles through the development of novel and efficient thermal management systems that use regerative auxilary power systems (RAPS) or engine waste heat to operate the A/C-R systems.

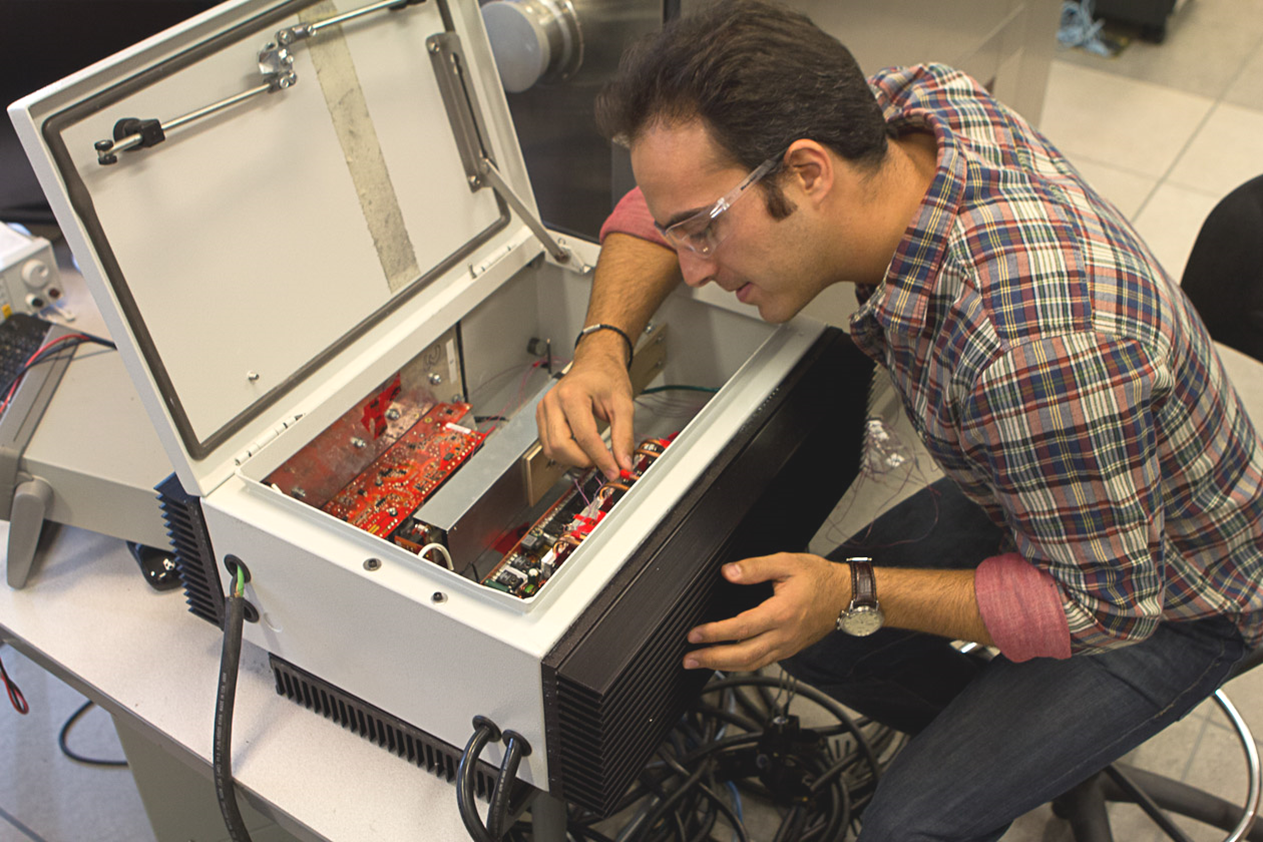

Cooling Solutions for High Power Electronics

The telecommunication and power electronics industries continue to develop compact systems with increasing power density and thermal load that requires effective, efficient cooling solutions. The LAEC is engaged in the design and demonstration of next-generation sustainable thermal management strategies that maintain device operating temperatures while reducing the parasitic power used by conventional active cooling systems. These solutions, featuring heat pipes and novel efficient naturally-cooled heat sinks, significantly improve system reliability while also reducing parasitic power draw, noise, and operating costs for cooling high power electronics.

The industrial partner on this project, Alpha Technologies Ltd., is an established leader in the area of power conversion and designs, manufactures, installs, and services powering solutions for worldwide telecom, Cable TV (Canada), traffic, security, medical, industrial, and renewable energy industries.

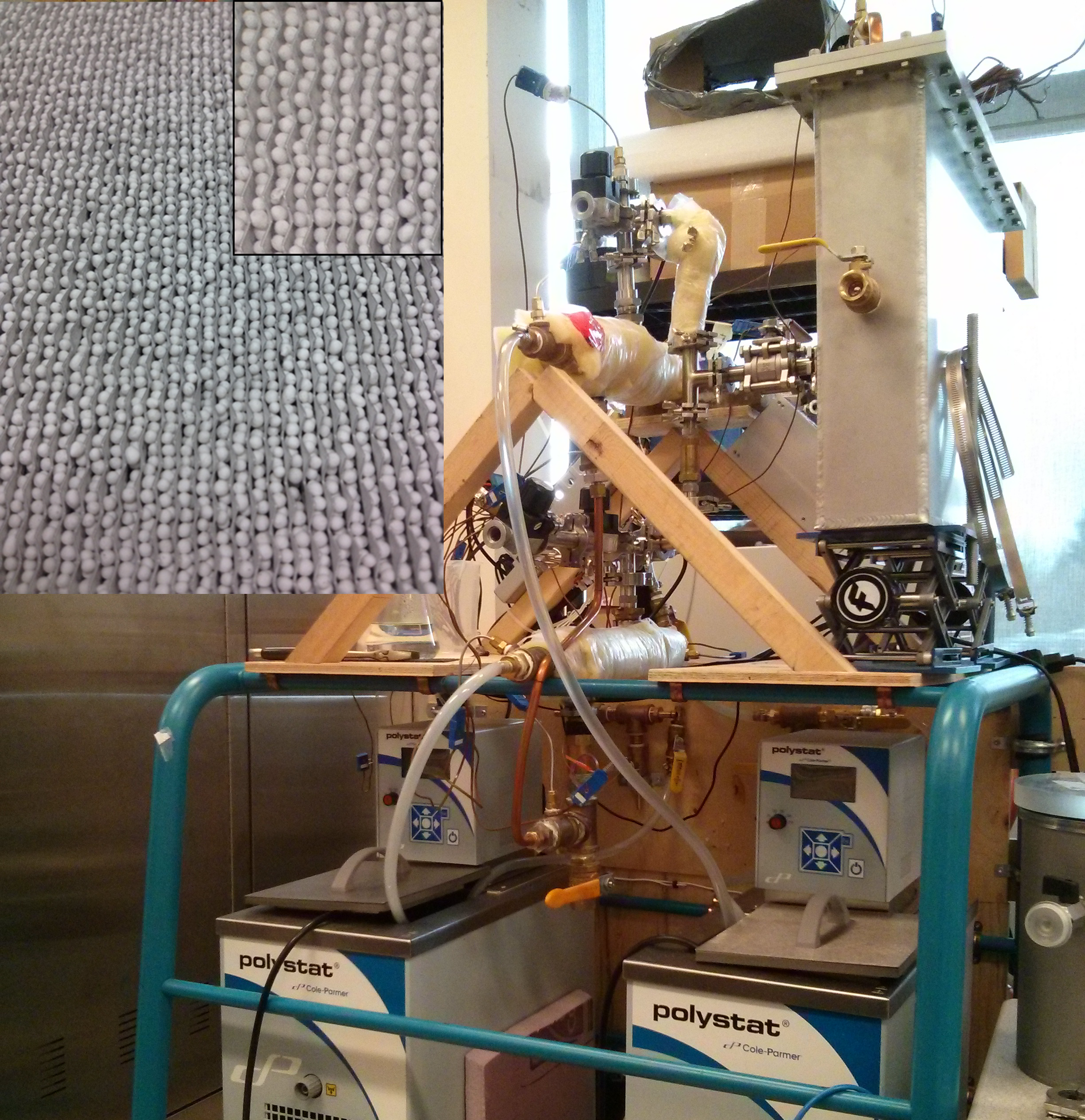

Adsorption Cooling System for Automotive Application

Vapour compression refrigeration and air-conditioning systems consume a significant amount of electricity and use hydrofluorocarbon refrigerants, which are known for their environmental impact as greenhouse gases. In heat-driven adsorption systems an environmentally-friendly refrigerant, e.g. water, is adsorbed by a porous material to create evaporative cooling. The adsorber bed is thermally regenerated, and therefore the cooling system can operate using waste heat (e.g. engine exhaust) or solar thermal energy.

LAEC research focuses on the critical challenges in this field, including the development of novel composite materials with high adsorption capacity, and high mass and thermal transport properties. Promising materials are tested in custom-built modular prototype adsorption systems that are further utilized to study adsorber bed design, evaporator and condenser heat exchanger design, and cycle parameters for the adsorption and regeneration processes.

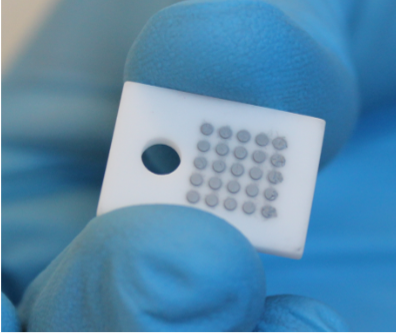

Transport Properties of PEM Fuel Cell Materials

The performance of a polymer electrolyte membrane (PEM) fuel cell relies on the effectiveness of the transport of heat, mass, and charge in a membrane-elctrode assembly (MEA). Accurate information about flow, temperature field, and associated heat transfer rates are particularly important to performance optimization and devising heat and water management strategies in hydrogen fuel cells.

The LAEC and the Automotive Fuel Cell Corporation (AFCC) are engaged in collaborative research focused on analytical modeling and experimental investigation of the transport properties of micro/nano stuctured fuel cell components. Of great interest is understanding the effects of transient and cyclic operating conditions such as compressive loads, relative humidity, and gas pressure on the properties such as thermal conductivity, diffusivity, permeability, and contact resistance in MEA layers.

Heating Ventilation & Air Conditioning (HVAC)

.jpg)

Air conditioning is a critical system for HEVs, as it is the second most energy consuming system after the electric motor.

Insulation Materials

This research program is focused on improving insulation technology, which is one of the most important aspects for saving energy that is otherwise wasted in the heating and cooling of enclosures, such as buildings, freezers, and reefers. The project is a collaborative research project between LAEC at Simon Fraser University and industrial partners Cool-It and Saputo. The long-term goal is to improve the praticality of aerogel composites by boosting their strength and lowering their implementation costs.

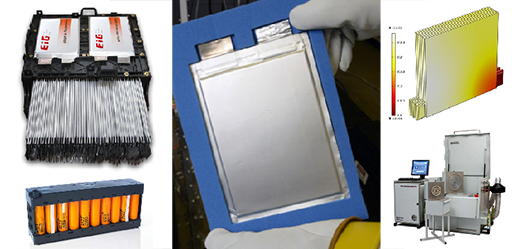

Thermal Management of Emerging Batteries

Thermal management is essential for safe and efficient operation of battery systems, especially for high-capacity polymer lithium-ion (Li-ion) batteries.

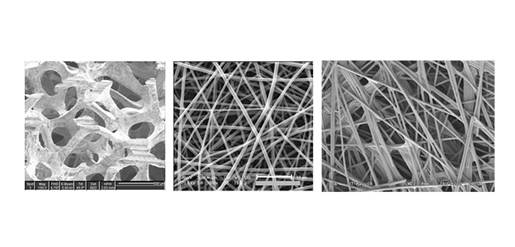

Transport Phenomena in Microchannels, Microstructured Materials, and Porous Media

Microstructured and porous materials are involved in a wide range of applications including composite fabrication, filtration, compact heat exchangers, fuel cell technology, and tissue engineering to name a few.