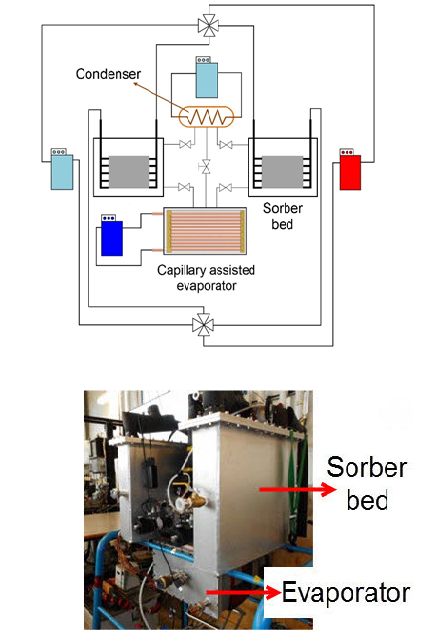

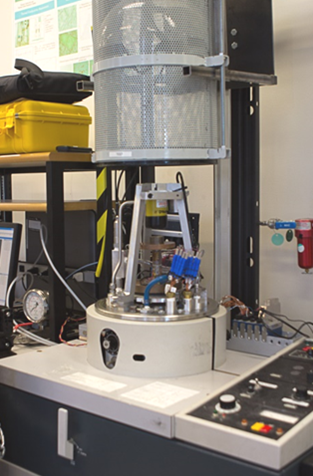

Two-Sorber Bed Sorption Test

The 2-sorber bed sorption test bed was custom-built in our lab to test different sorbent materials, sorber bed heat exchanger (HEX), evaporator and condenser in sorption cooling systems. Currently, a custom-designed capillary-assisted evaporator and a helical coil shell and tube HEX are used as the evaporator and the condenser, respectively. The sorber beds and the evaporator are placed inside custom-built vacuum chambers. Check valves are installed between the sorber beds and the condenser and gate valves are installed between the evaporator and the beds. A needle valve with high precision flow adjustment (Speedivalve SP16K, Edwards) and a U-tube are installed between the condenser and the evaporator. The whole system is vacuumed for 6 hours before the tests. Two temperature control systems are utilized to keep the evaporator and condenser at specific temperature. Furthermore, two temperature control systems are set to specific temperature vlaues for desorption and adsorption processes. Two four-way valves are employed to switch the heat transfer fluid between two sorber beds for desorption and adsorption processes. Type T thermocouples (Omega, model #5SRTC-TT-T-36-36) with accuracy of 0.75% of reading and pressure transducers with 0-34.5 kPa operating range (Omega, model #PX309-005AI) and 0.4 kPa accuracy are installed to monitor and record the temperature and pressure variations in each component of the sorption test bed over time. Positive displacement flow meters (FLOMEC, Model # OM015S001-222) with accuracy of 0.5% of reading are installed to measure the flow rate of the heat transfer fluid. The instruments are interfaced with a PC through a data acquisition system and in-house software built in the LabVIEW environment.

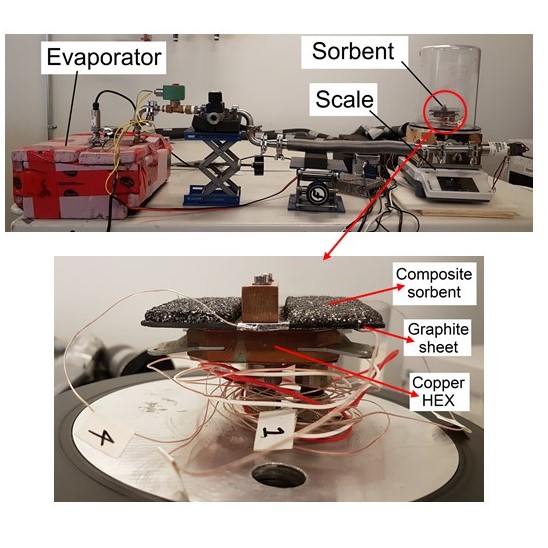

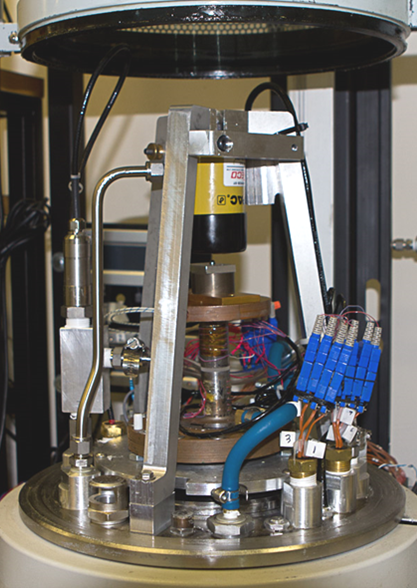

Gravimetric large pressure jump, G-LPJ

Gravimetric large pressure jump (G-LPJ) test bed was custom-built in our lab to investigate the heat and mass transfer performance of sorbent materials and the fins. Sorbent materials are coated on graphite sheets and bolted to a copper heat exchanger. The sorber bed and the copper heat exchanger are placed inside a vacuum chamber which is connected to a capillary-assisted evaporator/condenser. Heat transfer fluid is pumped through the copper heat exchanger and the evaporator/condenser, which sets the temperature of the sorbent and evaporator/condenser for sorption and desorption processes. The vacuum chamber is placed on a balance to measure the mass of the sorbate uptake. Moreover, the sorbent temperature and the pressure of the sorber bed and the evaporator are measured.

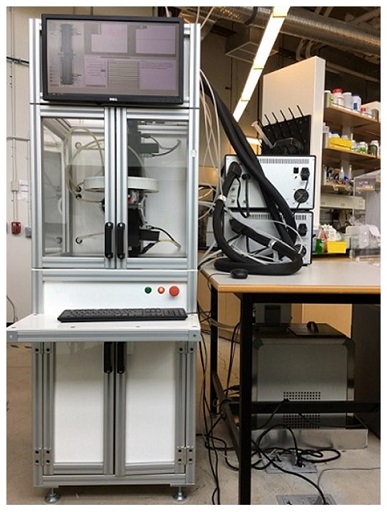

Modified Loschmidt Cell Testbed, MLC

MLC is a testbed capable of measuring oxygen diffusivity and permeability of porous layers with thicknesses in range of nanometers to millimetres, under variable operating temperature (room-85 ˚C), RH (0-95%), gas pressure (0-2 bar), and compression loads (0-50 MPa).

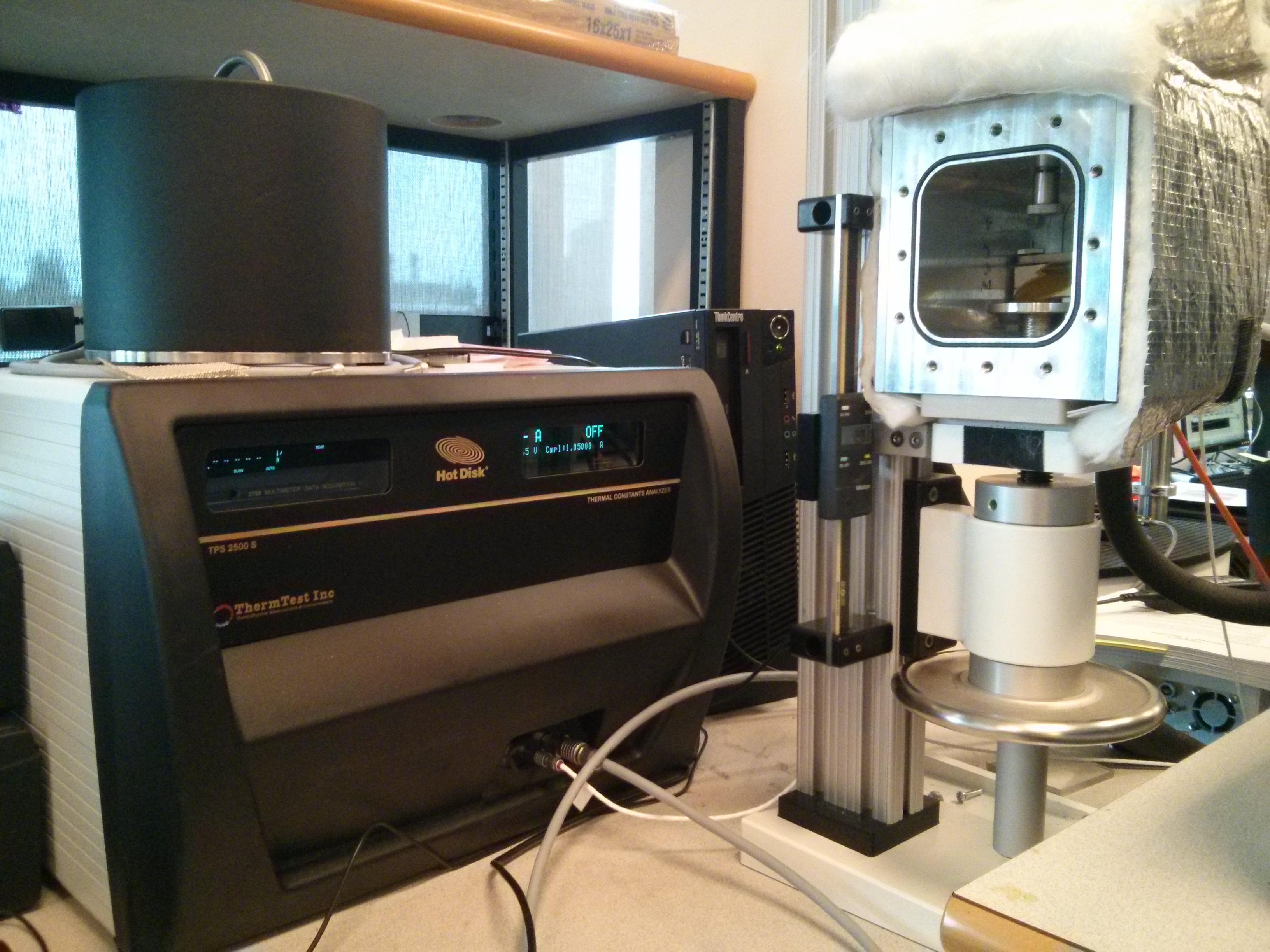

Thermal Constants Analyzer, TPS 2500 S

The TPS 2500 S is designed for precision analysis of thermal conductivity, thermal diffusivity and specific heat capacity of solids, liquids, powders, pastes and foams. I can also directly test the anisotropy of most specimens. Our TPS can operate in the range of -35 to 200°C, measure thermal conductivity in the range of 0.005 to 1800 W/m/K, thermal diffusivity in the range of 0.1 to 1200 mm2/s and specific heat capacity up to 5 MJ/m3K. The TPS 2500 S meets ISO Standard 22007-2.

Thermal Conductivity and Thermal Contact Resistance Testbed

This custom-designed facility enables accurate measurements of thermal conductivity and thermal contact resistance of a wide variety of materials (porous media, polymers, metals, thermal interstitial materials, thin films, PCBs, layered structures, etc) under various compressive loads in gaseous environment (from vacuum to pressurized gases). The testbed includes vacuum chamber, loading mechanism, load cell, thermocouples, chiller, and DAQ.

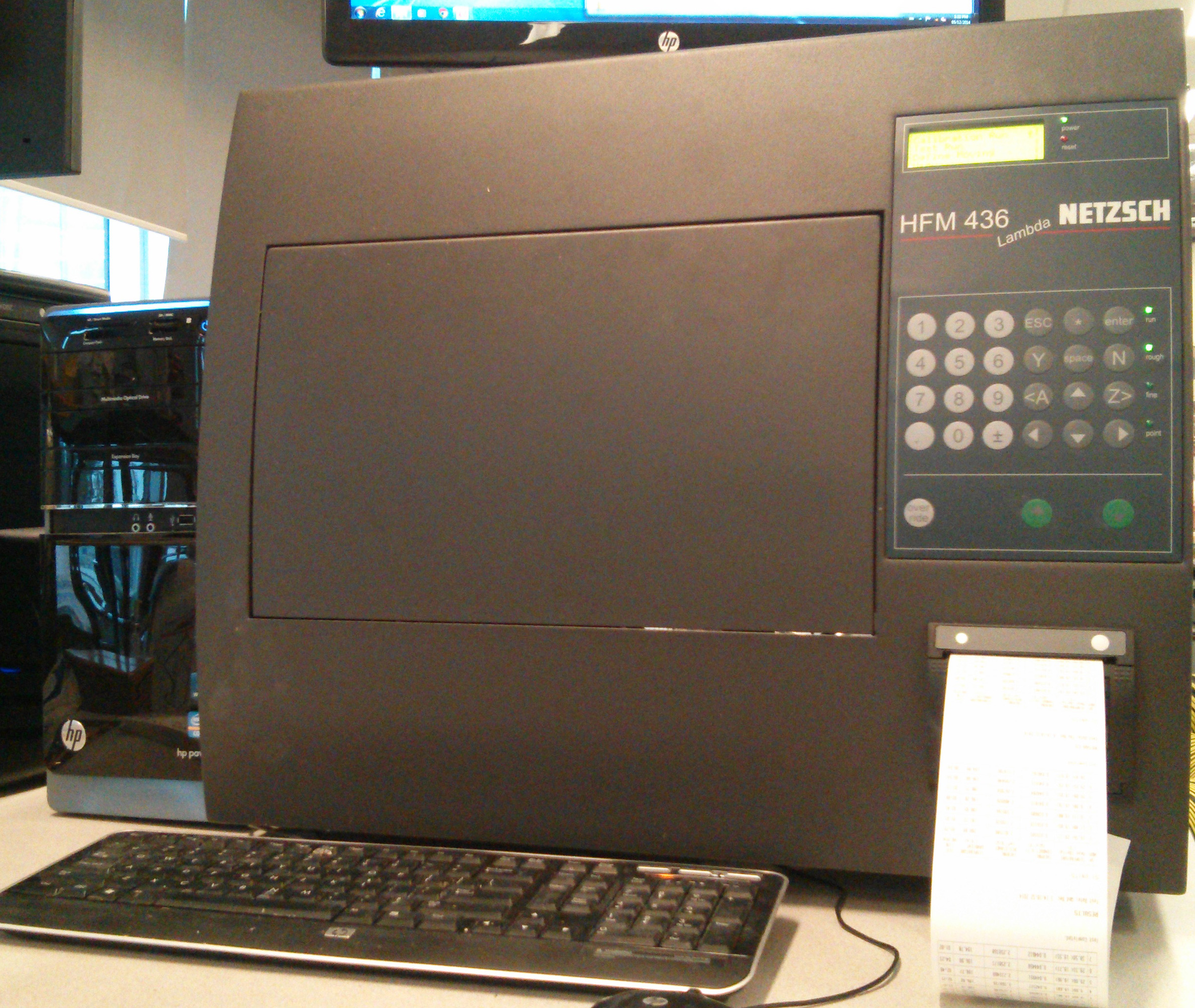

Heat Flow Meter, Netzsch HFM 436/3/1E

Heat flow meters (HFM) are exact, fast and easy-to-use instruments for measuring the thermal conductivity of low-conductivity materials such as insulations. A sample is placed between a hot plate and a cold plate and the heat flow created by the temperature difference is measured with a heat flux sensor. This instrument can handle samples measuring 305 mm x 305 mm and of variable thickness ranging from a few millimeters to 10 cm and the measurement temperature can be varied from -30 to 90°C. Thermal resistance can be measured in the range of 0.05 to 8 m2K/W and thermal conductivity in the range of 0.002 to 1 W/m.K. The HFM complies with ASTM C518, ISO 8301, JIS A1412 and DIN EN 12667.

Infrared Camera from FLIR

This IR camera can be used for capturing and recording thermal distribution and variations in real time, enabling accurate measurement of heat patterns, dissipation, leakage, and other temperature factors in a wide range of thermal management systems.

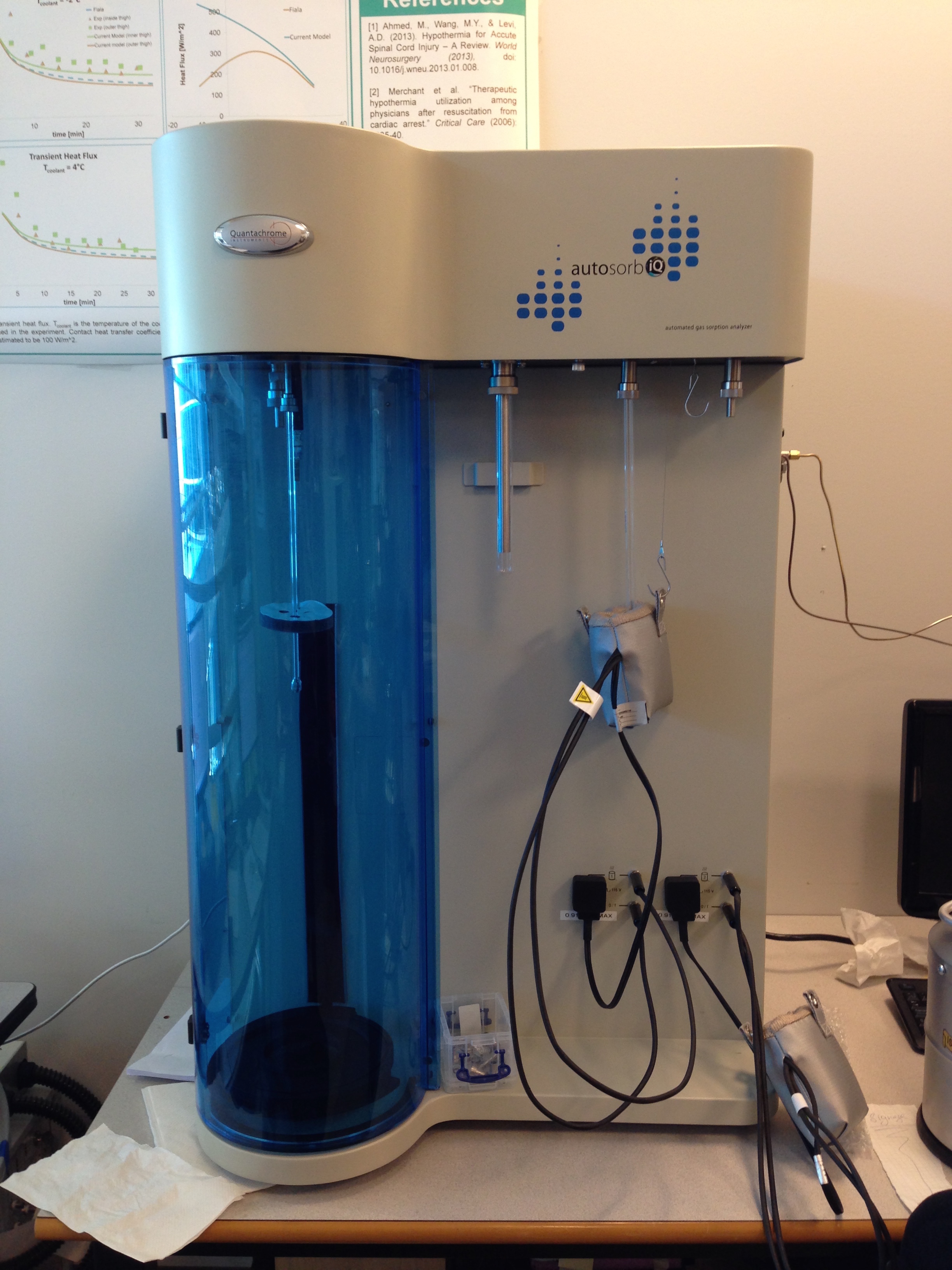

Autosorb-iQ from Quantachrome Instruments

Autosorb-iQ is a material characterization (porosimetry) device that determines material porous nature such as pore diameter, total pore volume, surface area, and bulk and absolute densities. It monitors the pressure changes in a calibrated volume sample cell to determine adsorbed volume of gas.

Thermogravimetric Sorption Analyzer IGA-002 from Hiden Isochema

This system measures the magnitude and dynamics of gas and vapor sorption of materials including pharmaceuticals, carbons, catalysts, zeolites, clays and polymer. Anti-condensation protection to 50 ºC is incorporated in the system which allows operation with water and an extensive range of hydrocarbon vapors. It operates with precise active pressure control ranging from ultra-high vacuum to 20 bar and a wide range of temperatures from -196 to 1000 °C.

Thermomechanical Analyzer (TMA Q400EM) from TA Instruments

The thermomechanical analyzer device (TMA Q400EM) measures sample dimensional changes under different conditions that can be controlled over time: temperature, force and atmosphere. The force can be applied using five different probes: expansion, macro-expansion, penetration, tension, and 3-point bending. With such capabilities we are able to do: coefficient of thermal expansion analysis, stress/strain behaviour analysis, bending/flexure property testing, glass transition temperature test, and melting and softening behaviour.

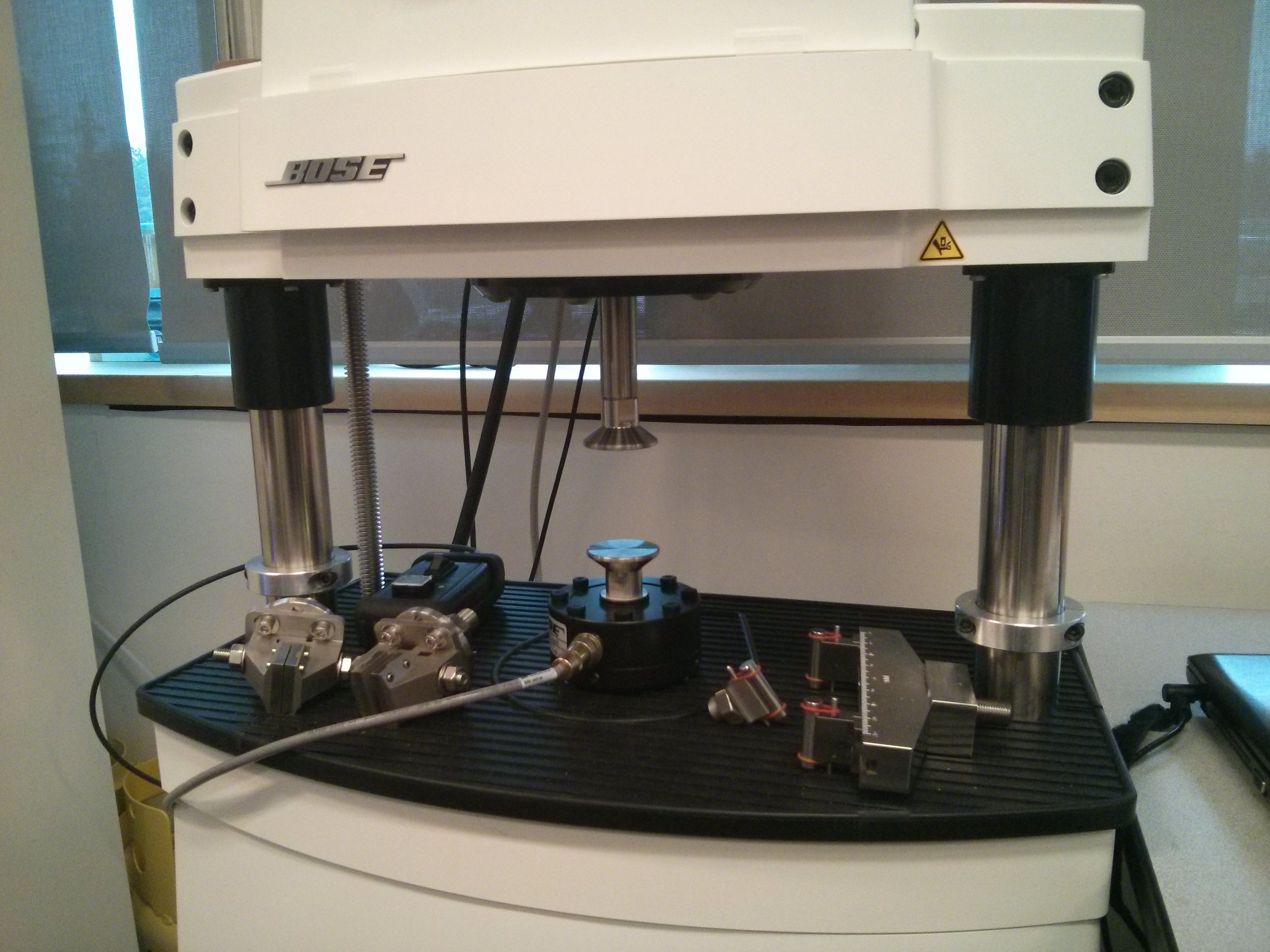

Bose 3330 Series II Mechanical Tester

Bose 3330 Series II provides control over force to determine material's dynamic characterization and mechanical fatigue with high accuracy. It can produce up to +- 3000N of force allowing variety of test application such as: tension, compression, bending, stress relaxation, creep, shear and pulsatile.

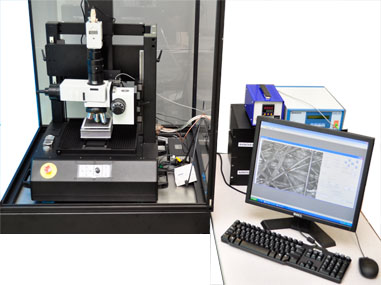

Nano-/Micro-indentation Testing Station from Nanovea

High precision nano, micro and macro hardness and elasticity modulus measurements for a wide range of materials and surfaces including thin films, polymers, metals, plastics, coatings, and substrates. Can perform Vickars hardness measurements as well as comply with ASTM E92 and E384.

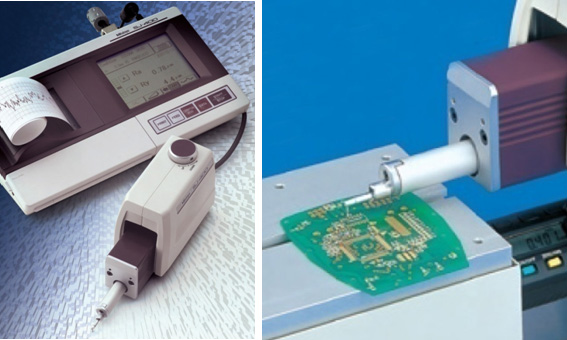

Surface Profilometer from Mitutoyo, Surftest SJ 400

This stylus type surface profilometer allows measuring a complete range of surface roughness characteristics that are required in interfacial transport analyses.

Environmental Chambers from ESPEC and Thermotron

These are large-scale ultra-cold temperature and humidity chambers with an interior volume of > 32 cu. ft (900 Liters), temperature range of -70 to 180°C(-94 to 356°F), and relative humidity range of 10% - 98%. With its unique 'forward looking' algorithms, electronic expansion valves for faster ramping, and improved refrigeration system these environmental chambers feature better stabilization and energy savings.

Humidifier from Cellkraft P-10

This precision flow through humidifier chamber is a compact and automatically operating unit to control the humidity, flow rate, and temperature of a gas flow. The device is suitable for flow rates in the range of 0 to 10 liters per minute.

Variable Speed Wind Tunnel from AIRFLOW Measurement Systems

This variable speed 1200 CFM airflow test chamber covers a flow range of 1.5 to 1200 CFM. The wind tunnel includes straighteners, calibrated nozzles for flow measurement, manual blast gate and a variable speed auxiliary blower.