Fall 2001

ENSC 220-3

ELECTRIC CIRCUITS I

Lab #3: RL and RC Circuits

OBJECTIVE:

You will wind (and test) your own inductor, which you will

also use in the AM radio project in a subsequent lab.

You will also investigate the properties of capacitors by making a simple

capacitor and by designing and testing filters and a simple capacitive switch.

PREPARATION:

Read Lab Handbook Sections:

2.3.4 Capacitors

2.3.5 Inductors

Appendix III (p. 280) on standard capacitor values.

EQUIPMENT:

Basic lab tools and breadboard (from your supplies)

Dual DC power supply

Digital Multimeter (DMM)

Function Generator (Wavetek 182A or equivalent)

Oscilloscope (Tektronix 2235 or similar)

LRC bridge

Operational amplifier (TL072)

Light emitting diode (general purpose, red)

Resistors (from open lab stock)

Capacitors (47 (or 56) pF, 330 pF, 10 nF, 1000 nF monoceramic, 1 uF)

Connecting wire

Wire and core for inductor

Emery paper

Tape

Materials for ``build-it-yourself''capacitor

NOTES:

Before connecting the power supply to your circuit,

preset the voltage and then

limit the current to approximately 25 mA.

(Use the techniques outlined in the Lab Handbook Section 2.2.2.)

When making circuit changes, switch off the power supply first.

Turn it on again only after checking the circuit carefully.

Take special care to observe the polarity of the IC (integrated circuit)

power pin connections (as specified in the data sheet for the device).

See Lab Handbook Section 2.3.6(d) 12 Ways to Kill or Wound an IC.

Arrange the components on you breadboard neatly and logically

to facilitate subsequent changes and troubleshooting.

See Lab Handbook Section 2.4.1 Breadboards.

(This section contains valuable info on using your breadboard.)

Use maximum power supply voltages of +/- 12 volts.

If your op amp circuits ceases to function correctly, consider that:

(a) you may have connected something wrong

(b) a component lead or wire is loose

(c) a short between two or more component leads occurred.

In most cases the op amp is alive and well,

unless you have done something very nasty to it.

If you do damage the op amp, determine exactly what caused the damage

and remedy the fault before replacing the op amp.

When operating the op amp from a single supply, us the MASTER section

of the supply, connecting the supply (-) to the (-V) pin of the IC,

and using this connection as the circuit common ground.

Check the multimeter setup before connecting it into the circuit.

Improper setup can give incorrect readings and/or damage the meter

or your circuit.

When operating the op amp from a single supply, us the MASTER section

of the supply, connecting the supply (-) to the (-V) pin of the IC,

and using this connection as the circuit common ground.

Be sure that DC offset on the function generator is set at "0".

Wind your inductor turns tightly together, taking care ti avoid ``pig-tails.''

Use tape to secure taps and ends of windings on your inductor.

See Lab Handbook Section 2.3.5(f) Winding Inductors.

After sanding the insulating varnish off the taps and lead-ends on your inductor,

and inspecting them carefully to ensure that all insulation is gone,

you may need to tin them using solder and a soldering iron.

See Lab Handbook Section 2.4.2 An Introduction to Soldering.

Note that this cannot be done with the continuously variable inductor,

because turns could be shorted by solder.

METHOD:

INDUCTOR:

1. Construction the inductor.

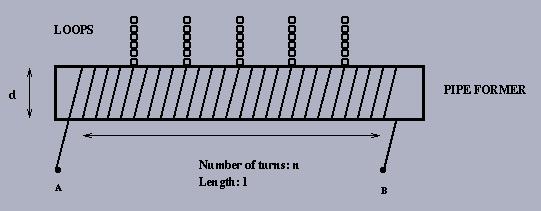

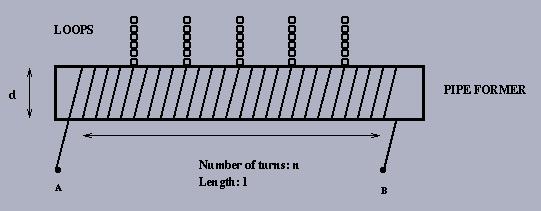

The inductance L of an air-core inductor is approximated by:

L = (d^2 n^2)/(18d + 40l)

where:

L = inductance (measured in uH)

d = coil diameter (inches)

l = coil length (inches)

n = number of turns.

You will be supplied with #26 AWG enameled wire (0.0170" diameter) and a

5" piece of nominal 3/4" (actual O.D.1-1/16") plastic pipe to construct your

inductor (you should not need any more than 30' of wire). You will probably

want to experiment with inductances in the range of 50 - 200 uH when you

finally build your AM radio. You can build a "tapped" inductor by inserting a

twisted wire loop "tap" at several sites along the inductor length:

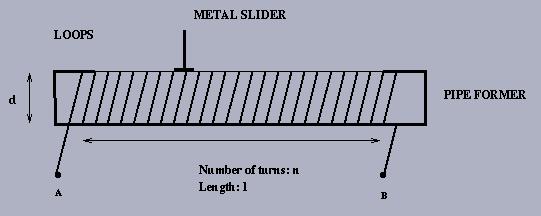

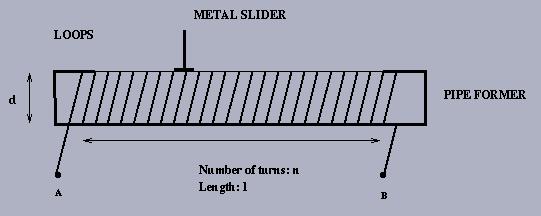

Alternatively, you can build a "variable" inductor by winding the inductor,

then use a piece of emery cloth (or fine sand paper) and lightly sand off

the enamel wire coating. Then run a metal "slider" across the exposed

windings to set up a variable tap:

2.

Use the LRC bridge to measure your total inductance and that of each tap.

Compare to calculation.

3.

Also devise your own method to measure the total inductance (e.g., based on

a step-response technique) using the terminal characteristic for an inductor:

v = L di/dt . Compare to calculation.

CAPACITOR:

1. Construct a capacitor.

You can make a capacitor with two metal plates (cross sectional area A)

separated by a dielectric of thickness d. Capacitance is determined by the

formula, C = eA/d (where e is a constant determined by

the material between the plates - the dielectric).

Construct a capacitor using any material you choose (plates: tin cans,

coins, tin foil, etc., dielectric: air, plastic film, paper, etc.).

2.

Measure the capacitance of your capacitor using the LRC bridge.

3.

Also devise your own method (e.g., based on a step-response technique)

using the terminal characteristic for a capacitor: i = C dv/dt.

HIGH PASS FILTER:

1.

Construct a simple RC high pass filter circuit, using your capacitor.

2.

With input level constant, sweep the input over a wide range of frequency

(sine wave), and plot the output level response.

3.

Repeat above using a capacitor of, say, 330 to 1000 nF instead of your

capacitor.

4.

Repeat using a capacitor of, say, 15 to 100 pF instead of your capacitor.

LOW PASS FILTER:

1.

Construct a simple RC low pass filter circuit, using your capacitor.

2.

With input level constant, sweep the input over a wide range of frequency

(sine wave), and plot the output level response.

3.

Repeat above using a capacitor of, say, 330 to 1000 nF instead of your

capacitor.

4.

Repeat using a capacitor of, say, 15 to 100 pF instead of your capacitor.

CAPACITIVE SWITCH:

1.

Use your capacitor (along with an op amp(s) circuit) to produce a simple

capacitive switch. The switch should be designed to operate as follows:

2.

Pressing on the capacitive element should alter its capacitance.

Explain how.

3.

Assuming a sinusoidal input, devise a circuit whose output amplitude

depends on C. Experiment with different frequencies from 10 kHz - 1 MHz,

and possibly with the R and C in your circuit, to obtain a maximum change

in output level when your capacitor is pressed. If possible, try to get at

least a 1.5x to 2x level change.

4.

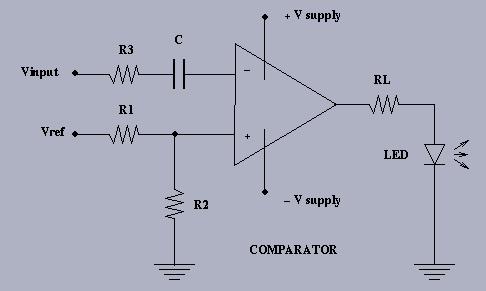

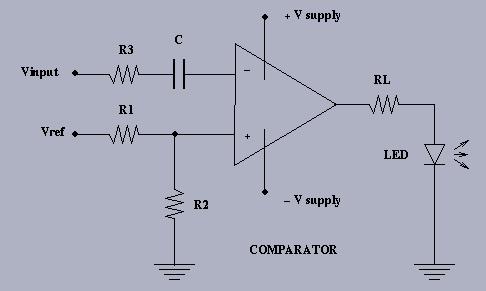

Measure the change in this output using a simple comparator circuit.

5.

Process the output of this comparator so that you get a DC signal that goes up

and down as you press on your capacitor. This can be done by choosing and

setting an appropriate reference voltage on the comparator.

6.

The comparator output should ``switch'' on an LED wired in series with

a current limiting resistor as shown below.

The resistor RL inserted between the comparator output and the LED is

used to limit the current through the LED.

See Lab Handbook Section 2.3.7(a) LED.

Refer to ``Testing an LED'' for information on lead identification.

You can try several resistors to adjust the intensity to your liking. The

LED conducts current in one direction only (in the direction of the arrow)

so you may have to reverse the LED connections if it does not light the

first time.

If you want to read more about diodes (the device you are using is a Light

Emitting Diode - LED) then you can refer to Chapter 6.

Your lab write-up should investigate a number of considerations

(design, analysis, measurements, observations, testing, calibration, etc.)

for all these experiments.

Last modified: Tuesday October 30 16:06:59 PST 2001.