Bluetooth Speaker

Group of 4 | Designer/Engineer/Prototyper

I, along with three group partners, envisioned and built a bluetooth speaker product made out of plaster and wood. The product would be able to be sold at a reasonable price, cater to environmental concerns, and give the buyer a sense of playful yet functional speaker.

In this project I wanted to use my design skills to create technology that can be placed in the modern day home and not be intrusive to the environment around itself. I took part in every aspect of the project including the design, material considerations, prototype, and final production of the speaker.

Initial Considerations

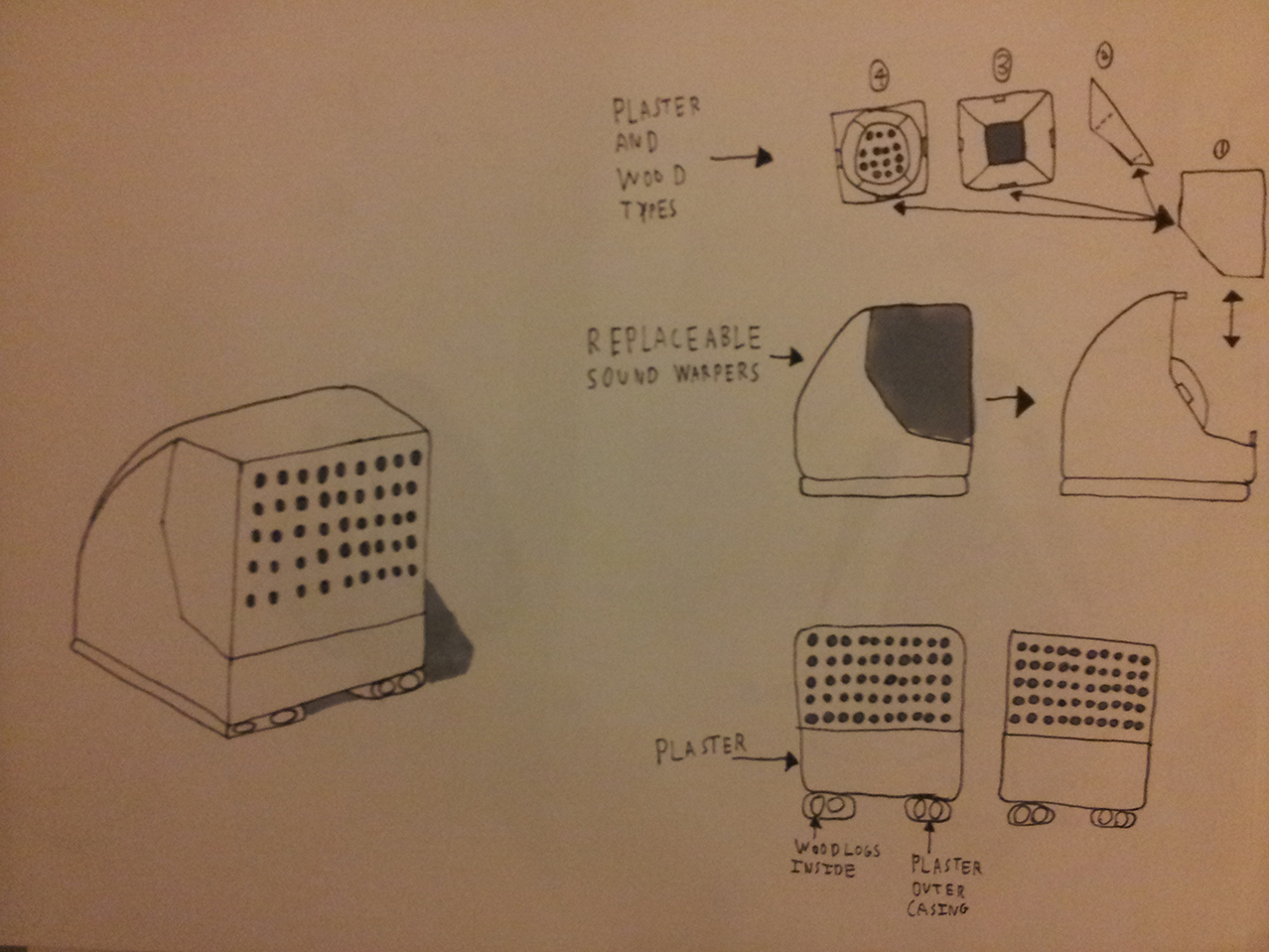

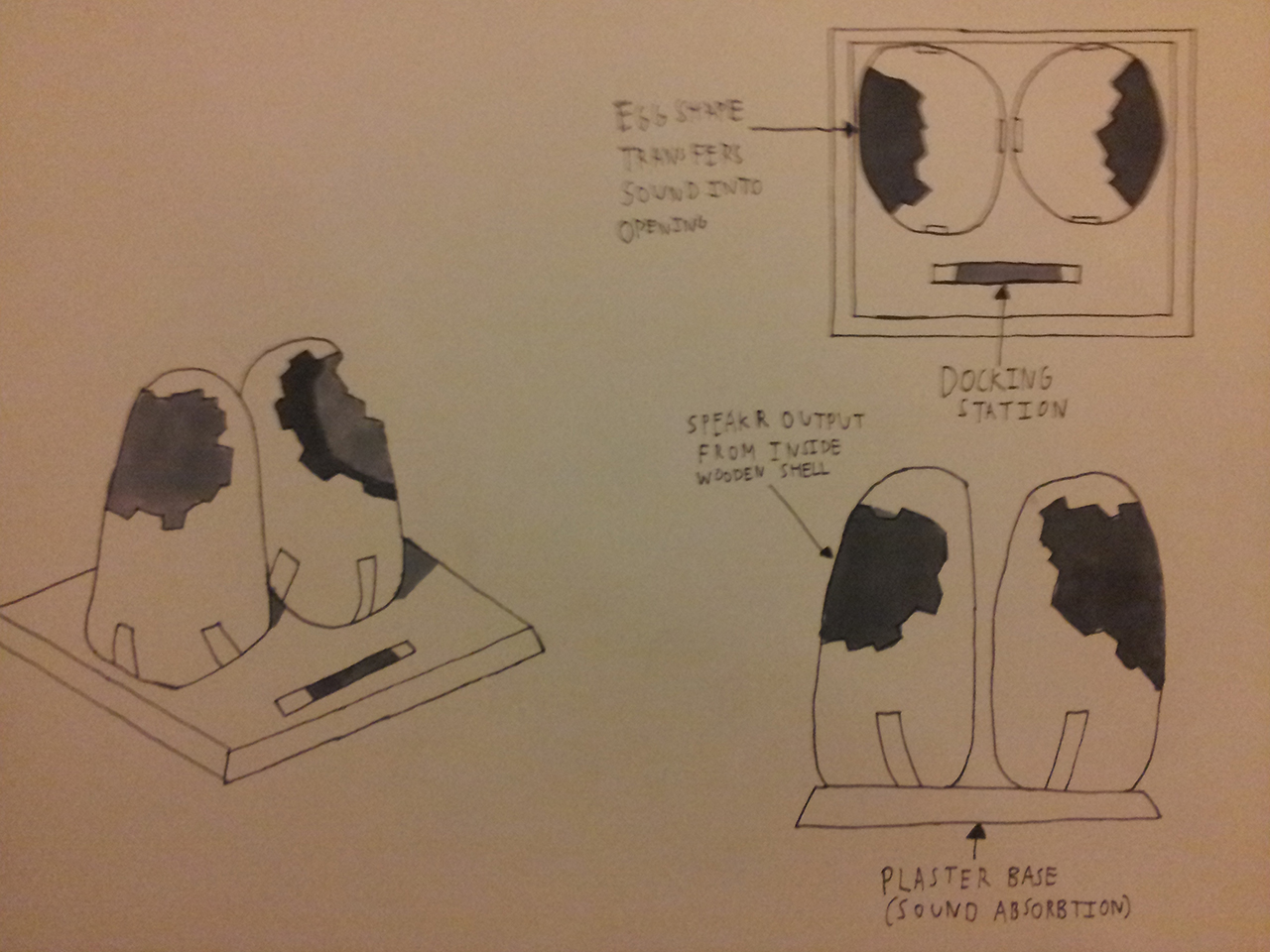

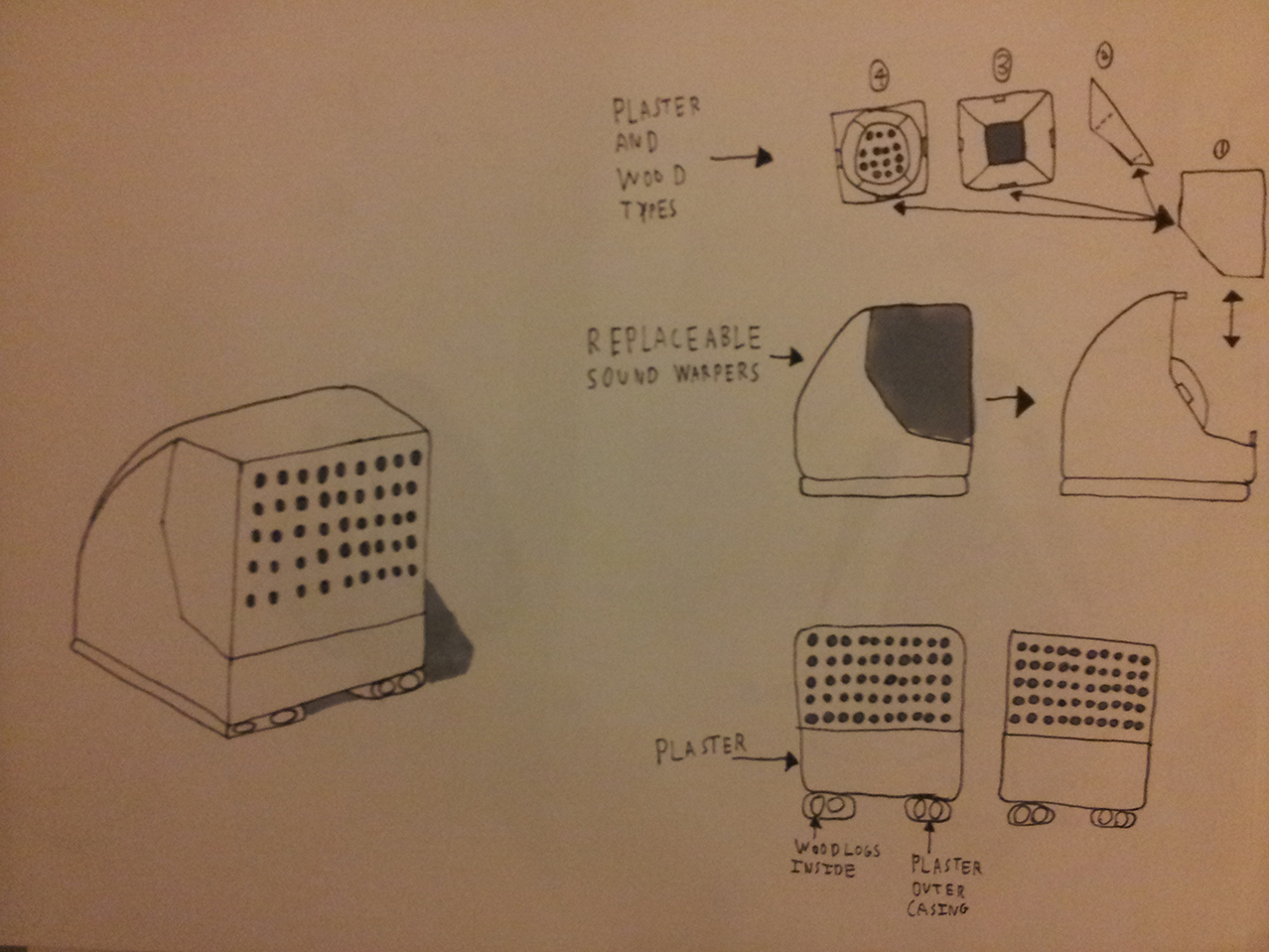

Two of many designs brainstormed throughout the first iteration process

Through an iterative process, quick ideas were churned out to be able to view a large amount of angles to imagine the speaker. The designs were drawn on paper to quickly allow inspiration to flow. We then condensed the designs into a few final ones and redrawn with higher details and then out of those choose one to draw in illustrator as the base to create the speaker.

Prototyping and Development

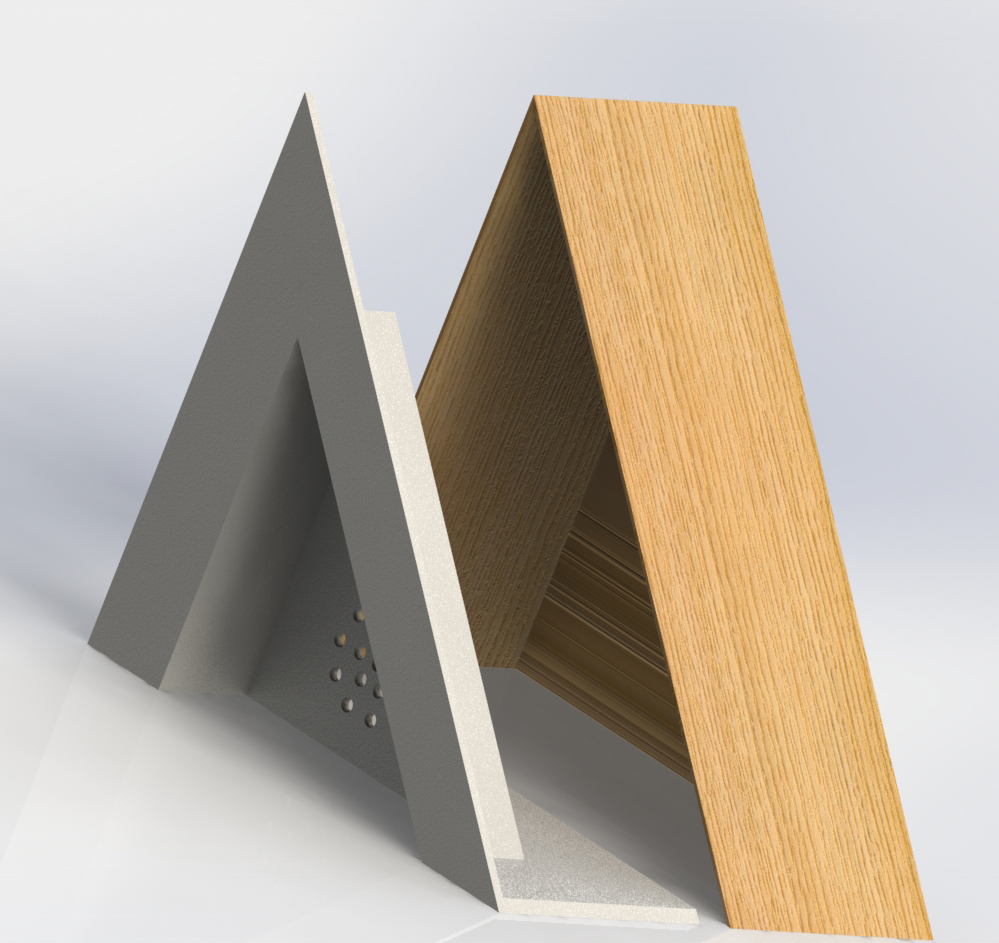

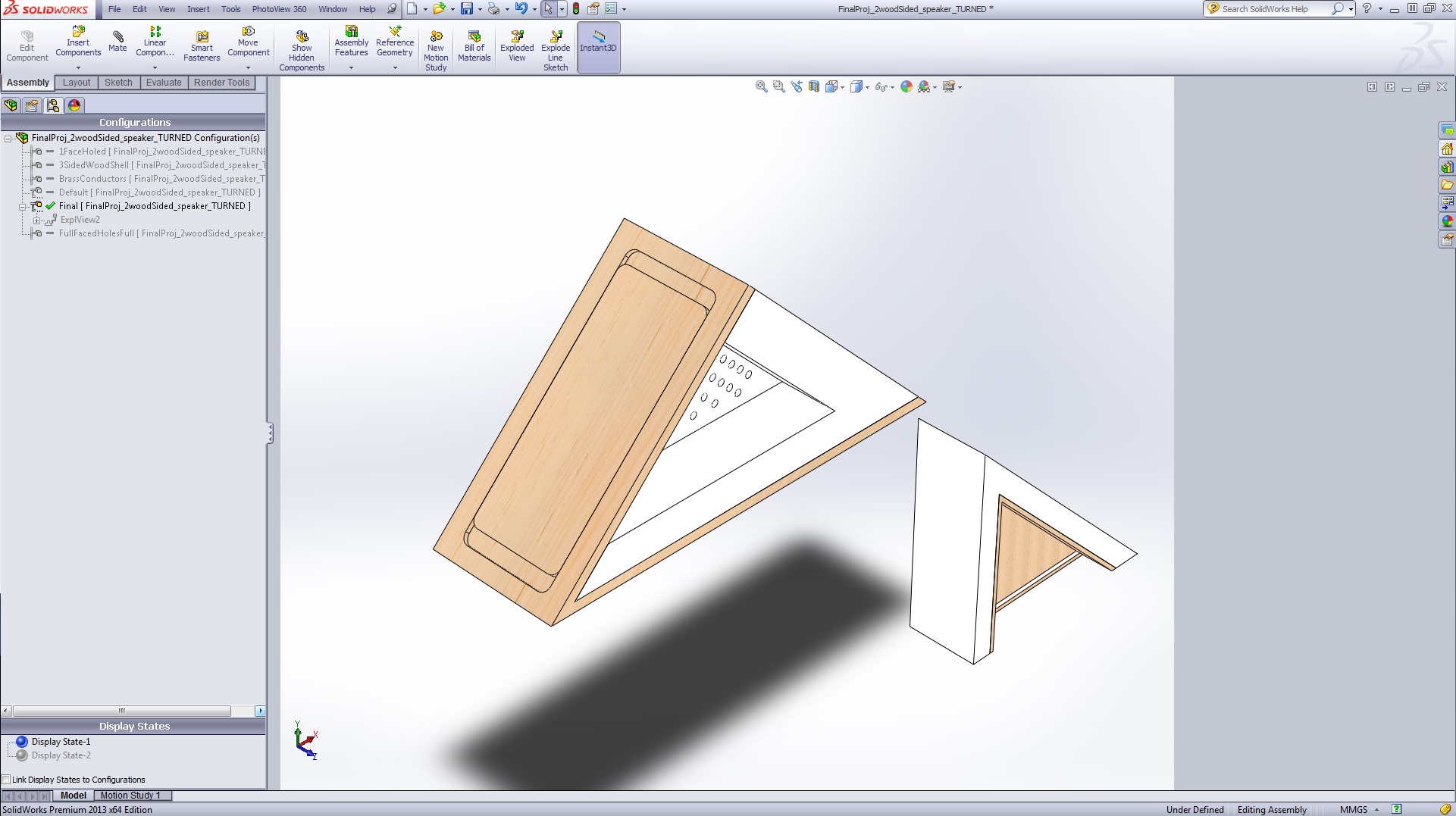

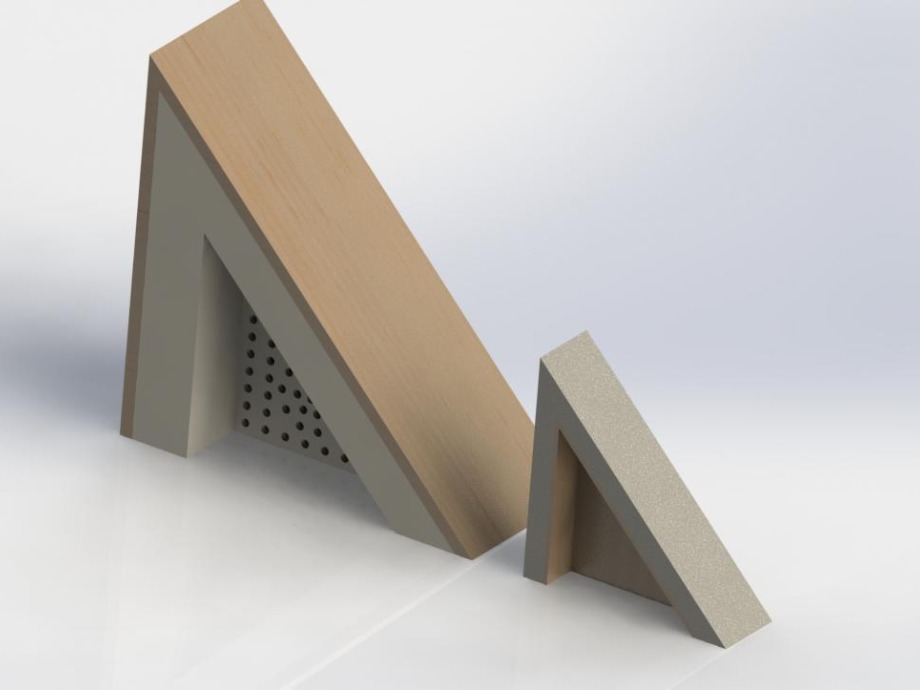

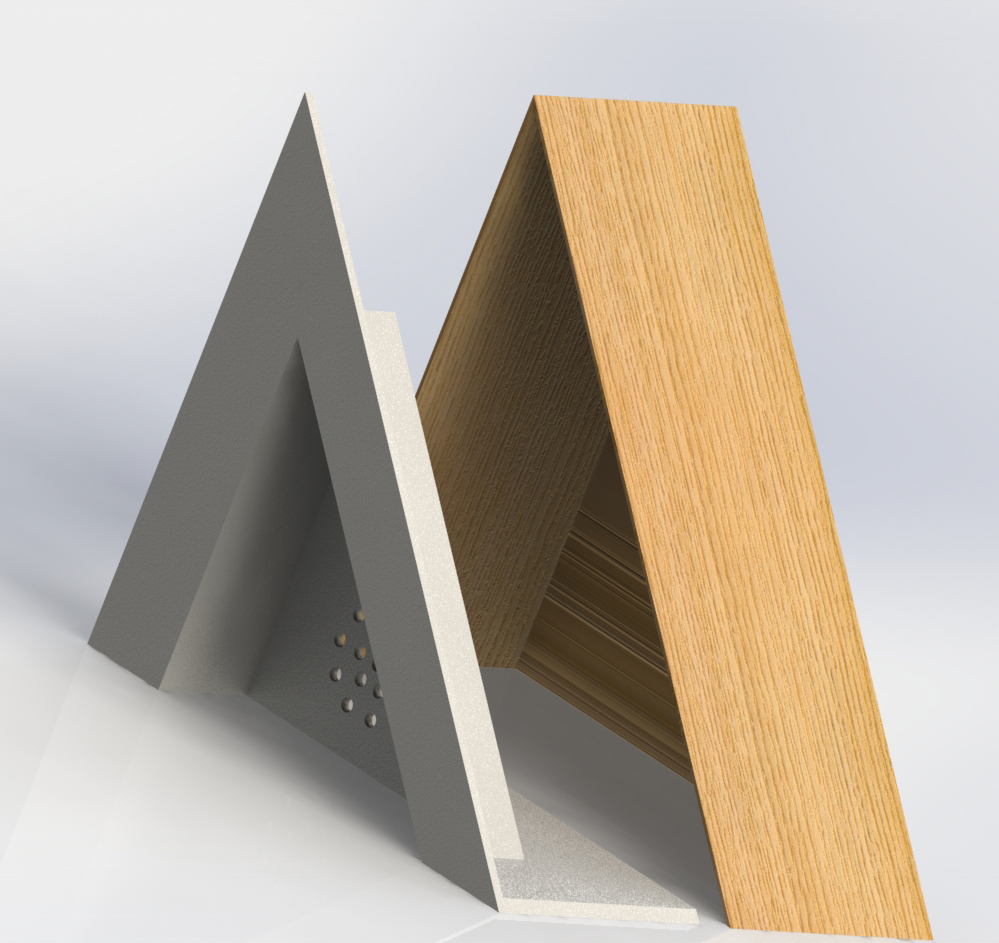

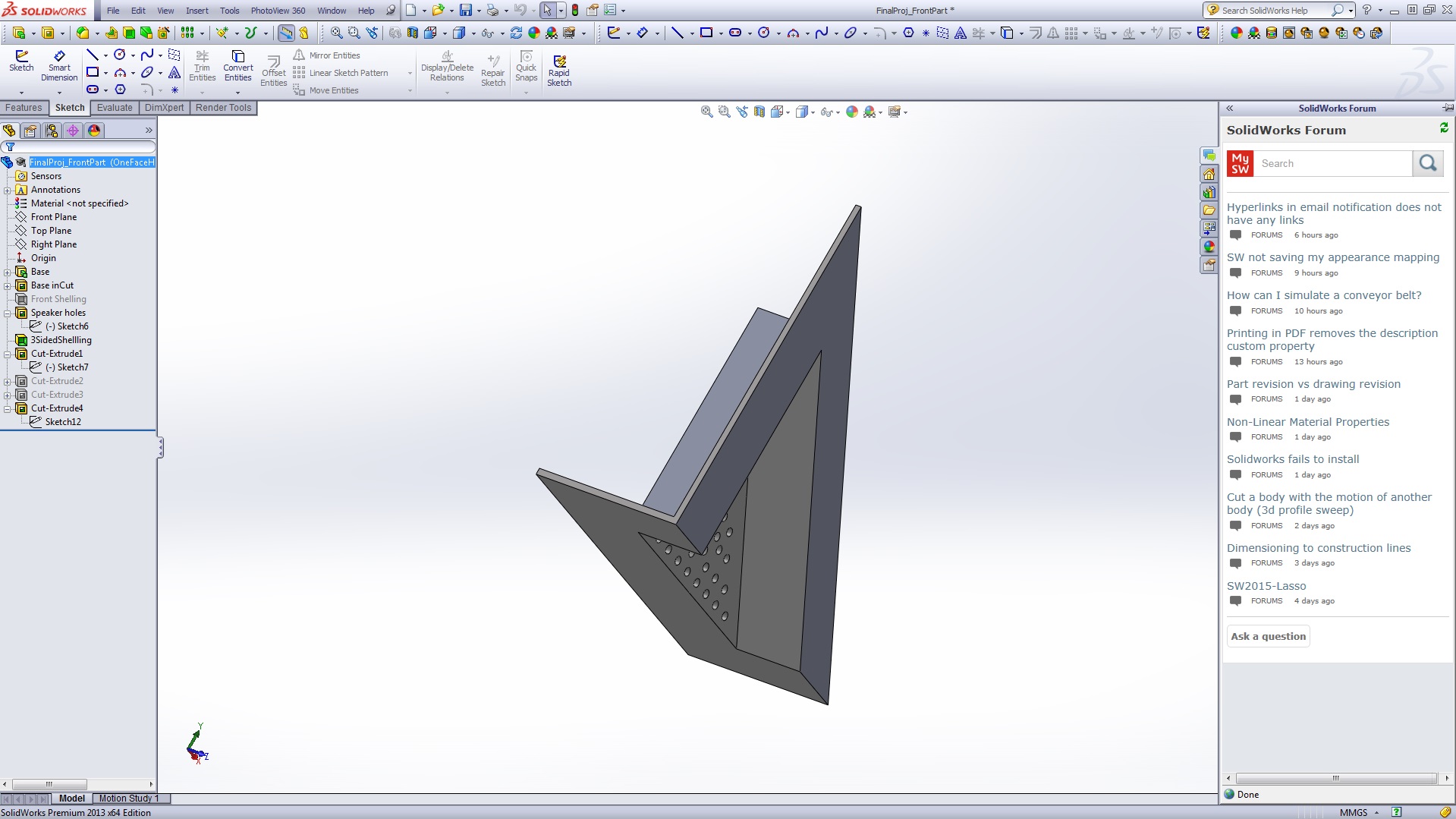

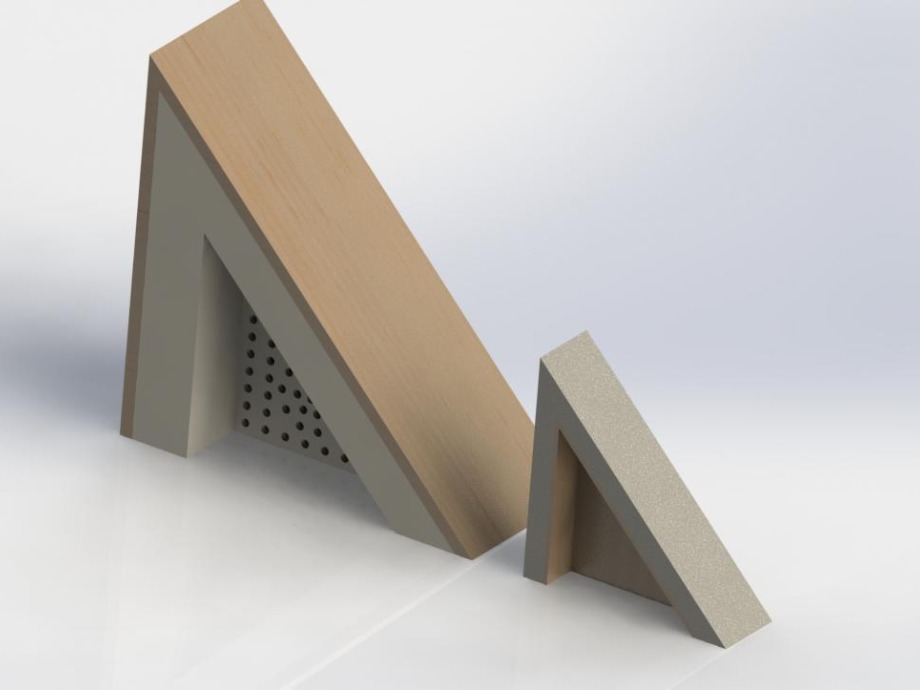

Higher fidelity made in Solidworks

The speaker was modeled in SolidWorks to better understand the dimensions needed to build a physical model

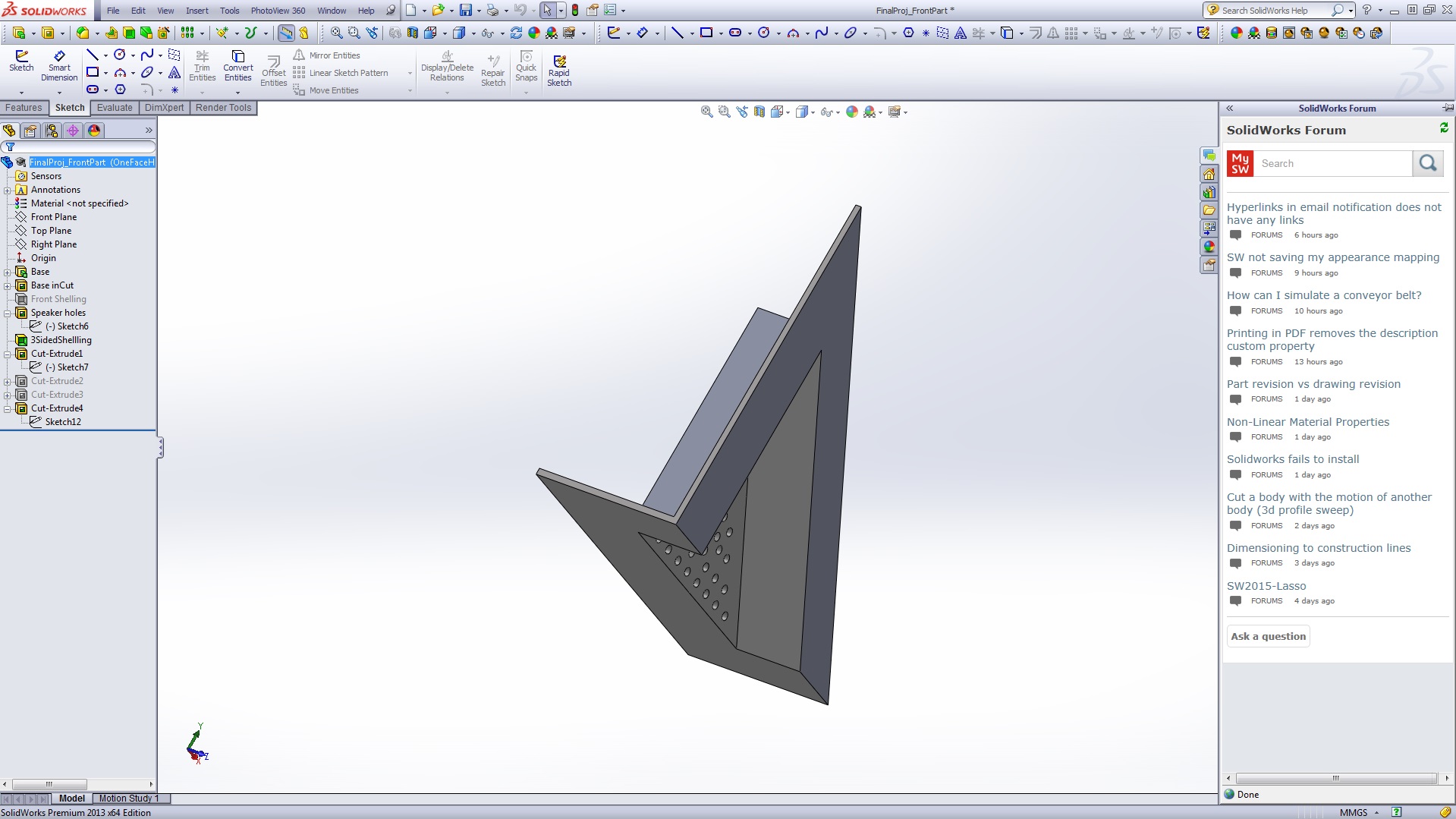

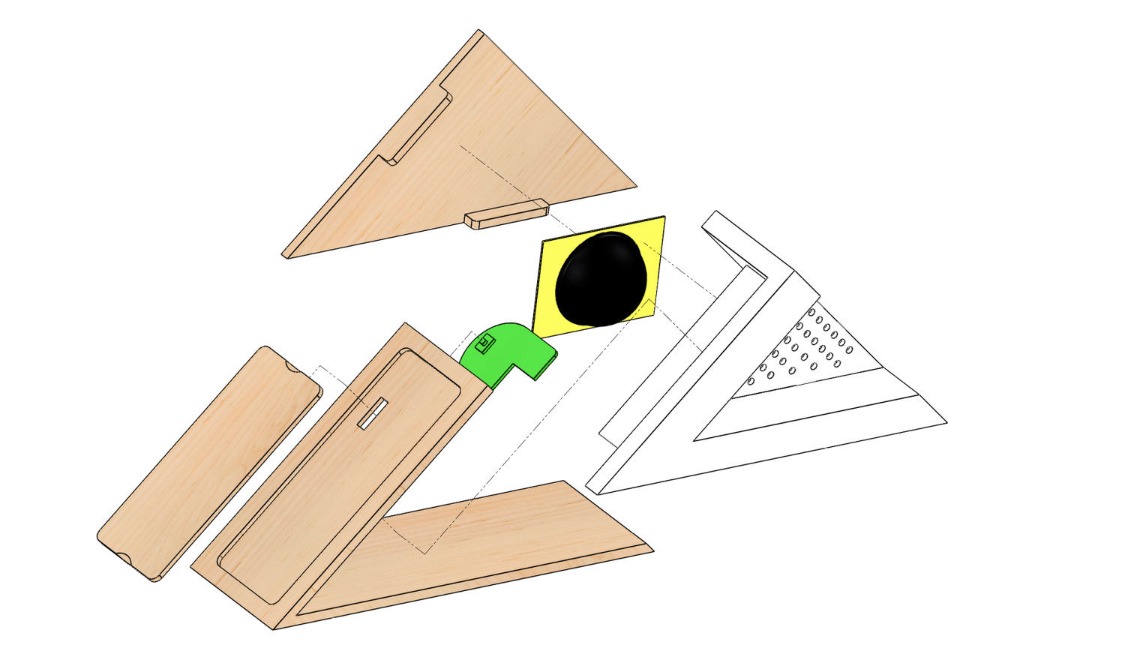

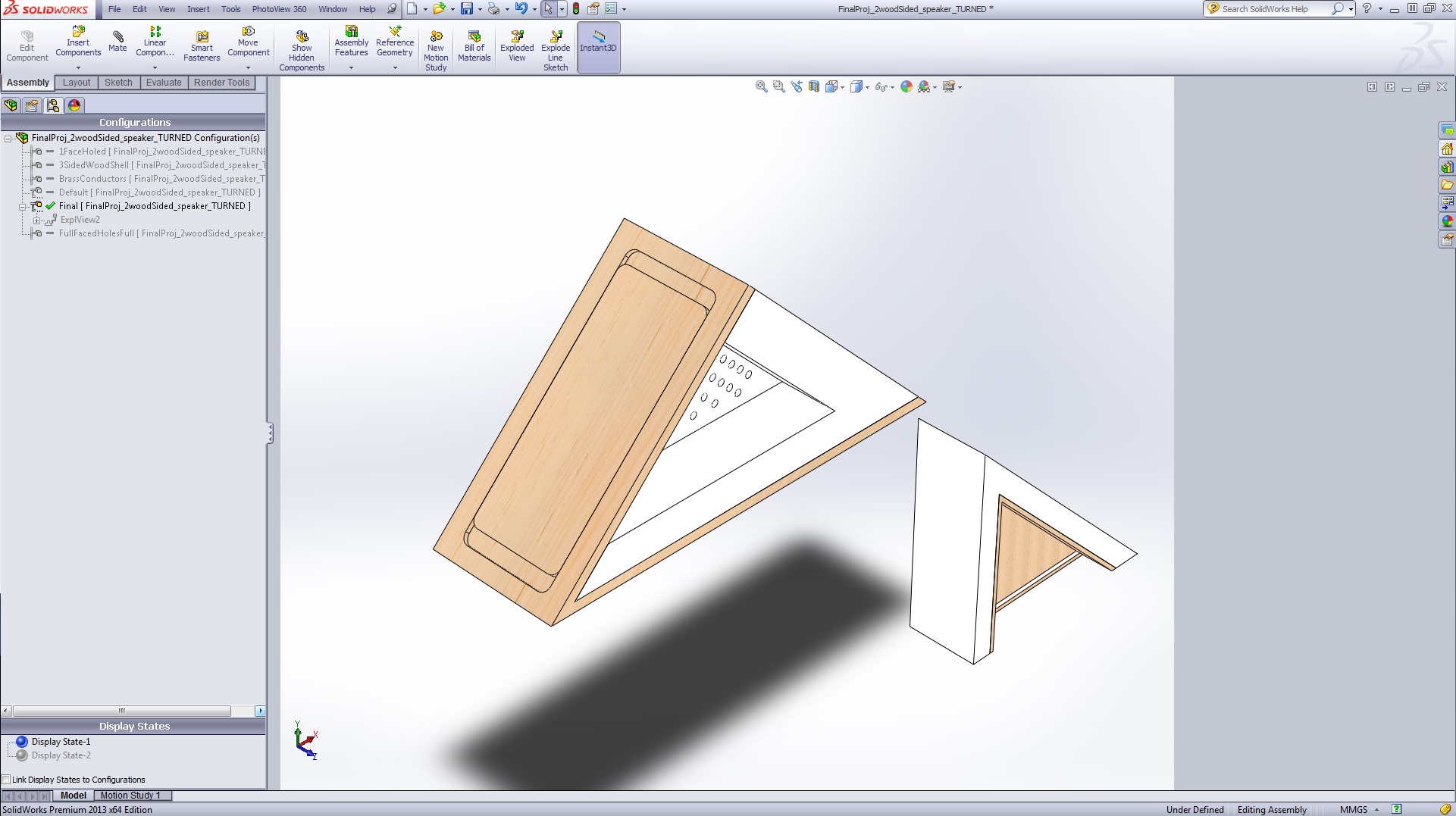

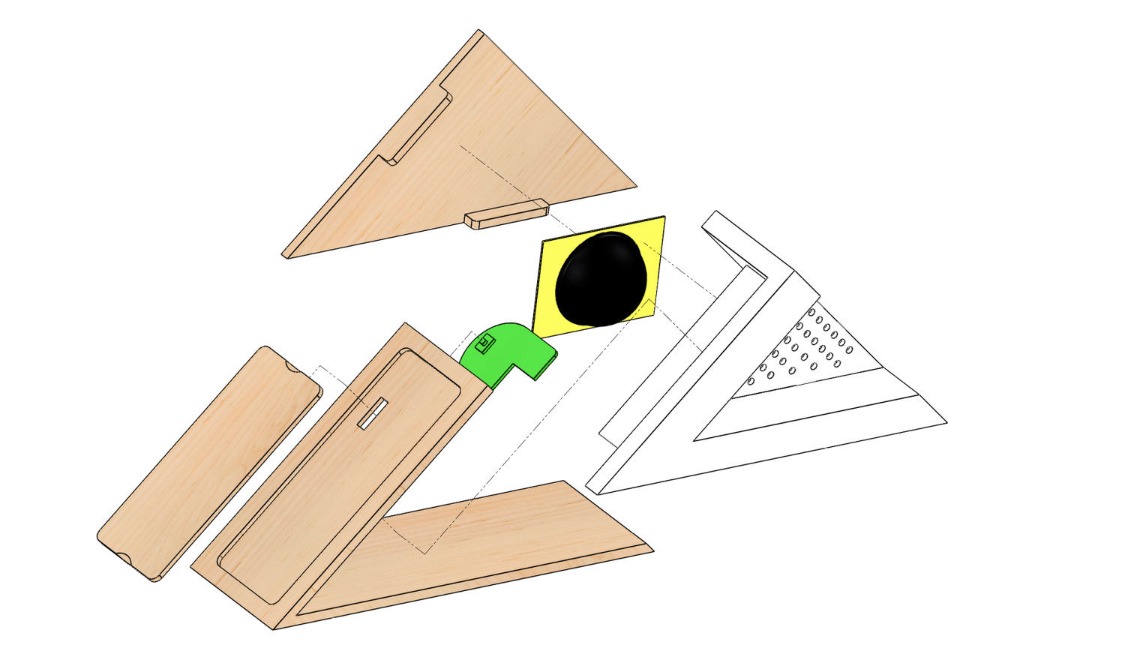

The components of the speaker pieced togather in Solidworks.

A 3D rendition of a blueprint for the speaker to show how each piece would fit where together

The final designs took form as it was built piece by piece in solid works and then put together. The design chosen was a triangular type with other speakers of the same variety able to stack and placed together.

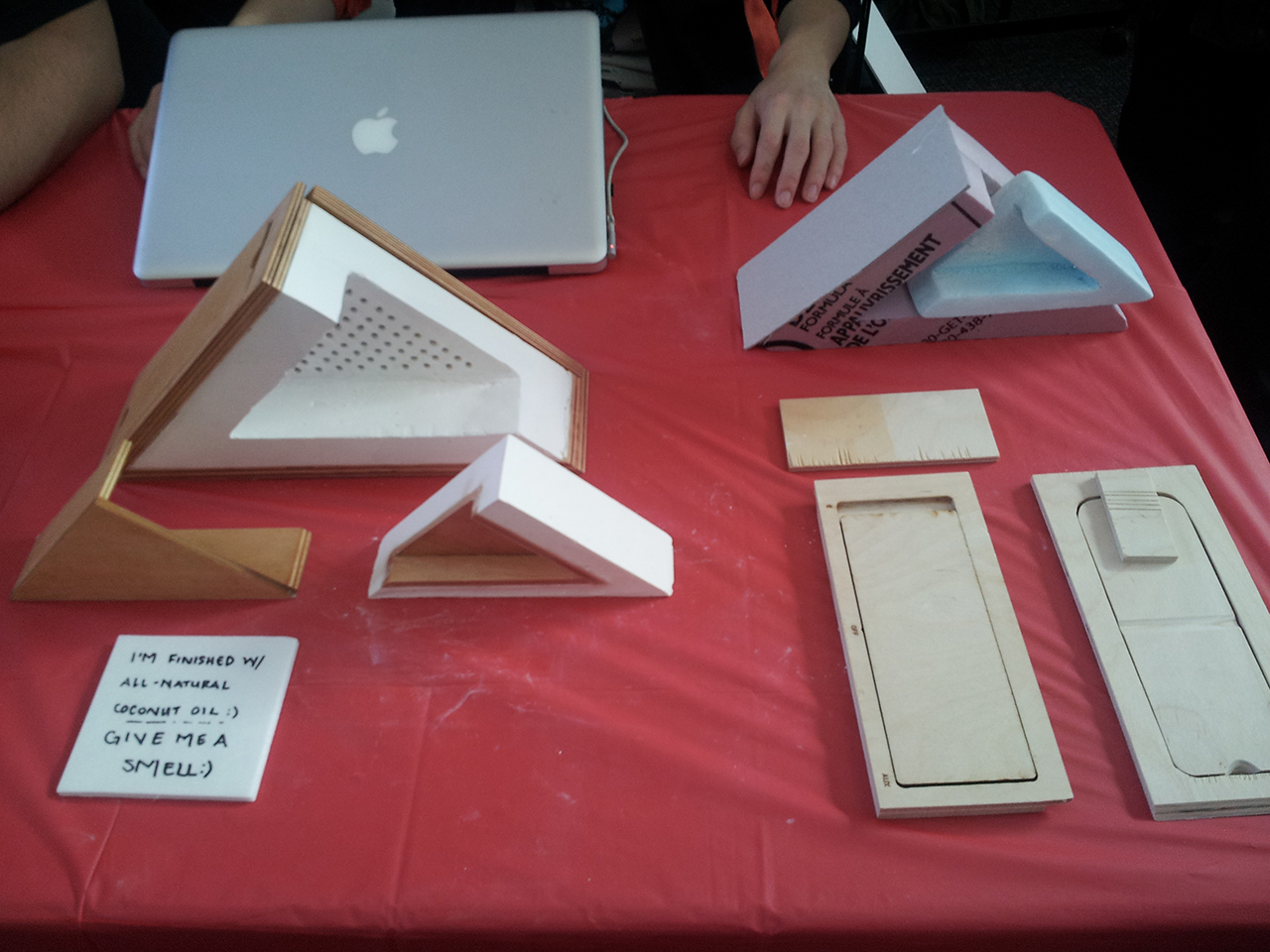

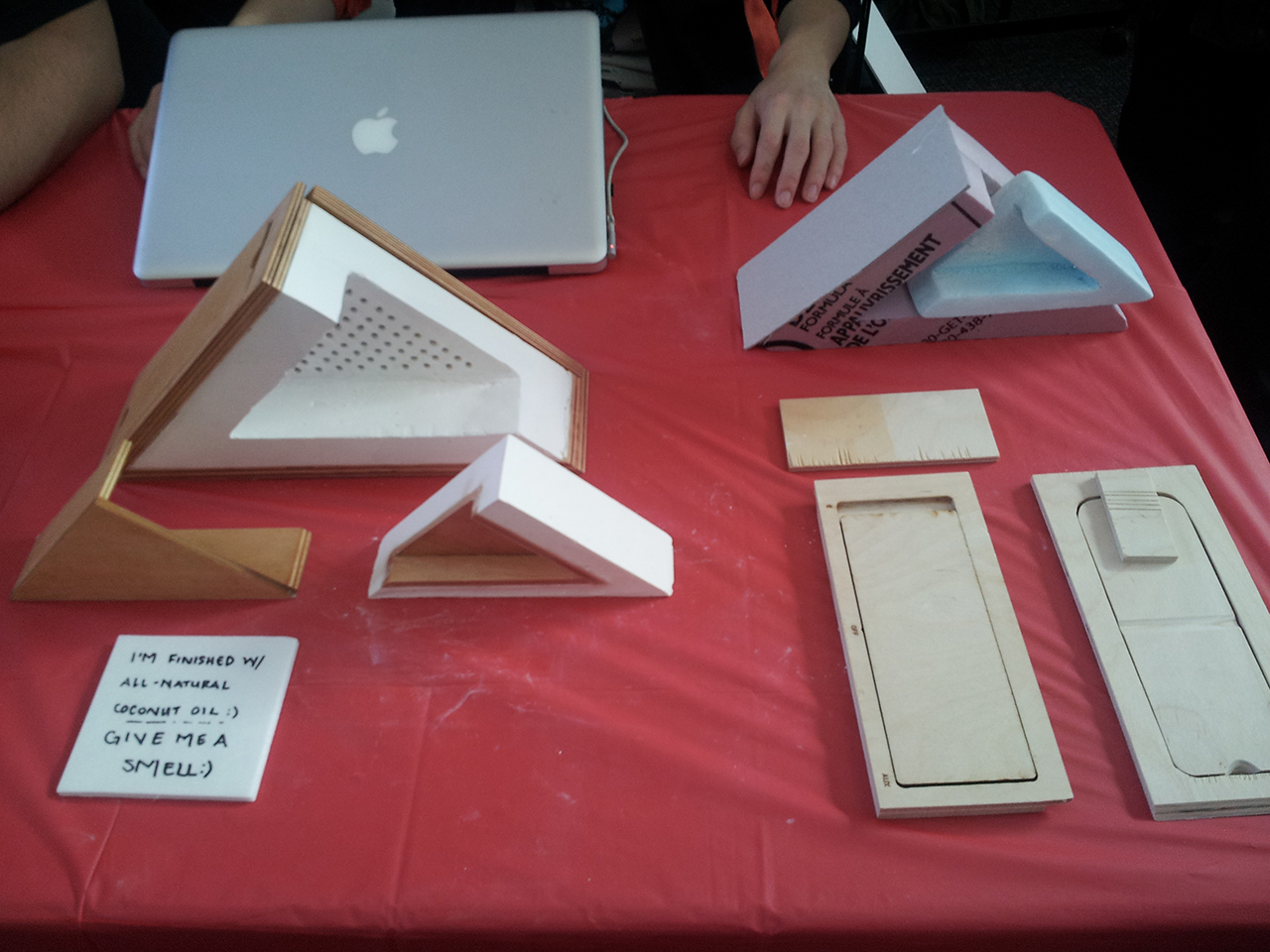

From digital blueprints to physical creation, this is the mold for the plaster parts

A rough physical prototype was created out of foam which then took to Solidworks to refine measurements. Renderings of the device's parts were created as well as placed on a blueprint in Solidworks to help in the creation of the final product to avoid mistakes or misplacements. Parts were then created through laser cutters for wood and by molding for plaster which came out well due to the preparations made beforehand.

Final Iteration

The final product showcased along with foam prototypes.

The final product was made and presented as a showcase to the general public. I was very happy with the finished product and it worked as a bluetooth speaker. The built product was the best way to show it to others.